I see many teams guess box sizes and then fix problems later. Waste follows. I want to stop that. I show simple steps. I use real shop habits.

Use a rigid tape. Place the box on a flat surface. Measure the longest horizontal edge for length, the shorter horizontal edge for width, and the vertical edge for height. Record external and internal sizes separately. Note units. Double-check each read.

I will walk through the method. I will show fast rules. I will also show pro tips I use in my display factory. Stay with me for a few minutes. You will avoid rework and returns.

What is the correct way to measure a box?

Many people hold a tape in the air and read a number. The number looks fine. Later the product does not fit. Stress rises. I solve this with a short routine that I teach to my new staff.

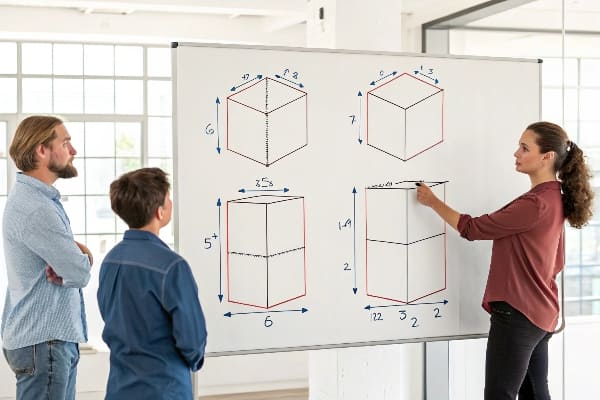

Set the box upright. Measure length (longest side on the base), width (shorter side on the base), and height (top to bottom). Read to the nearest millimeter or 1/16 inch. Write L × W × H with units. Repeat once to confirm.

Step-by-step workflow

*1. Set orientation

I set the box so the opening faces up. I keep two base edges flat on the table. The longest base edge is my length. The other base edge is my width. The vertical edge is my height. This keeps my team aligned across projects.

*2. Tools and accuracy

I use a steel tape or a Caliper for small features. Cloth tapes stretch. That adds error. I read to 1 mm or 1/16 in for shipping cartons. I read to 0.5 mm for inserts or fit-critical trays.

*3. Inside vs outside\

External size1 drives logistics and shelf space. Internal size2 decides fit. Corrugated boards add thickness. Single-wall E-flute adds \~1.5–2 mm per wall. Double-wall adds more. I list both sizes in my spec to avoid guessing.

Common orientation rules

| Term | What I pick | Why it helps |

|---|---|---|

| Length (L) | Longest base side | Aligns quotes and CAD files |

| Width (W) | Shorter base side | Avoids swapping with height |

| Height (H) | Vertical edge | Matches shelf clearance checks |

| Interior (ID) | Size inside walls | Ensures product fit |

| Exterior (OD) | Size outside walls | Ensures pallet and shipping fit |

I learned this the hard way. Years ago a countertop display failed to fit a glass case by 3 mm. We measured only outside. We forgot an acrylic lip. We now log OD and ID on every drawing. No more surprises.

How to calculate the dimensions of a box?

People mix up raw reads and useful numbers. A number on a tape is not a full spec. A good spec includes tolerances, flute type, and wall adders. I keep a simple math checklist for my team.

Record L, W, H as L × W × H. Add board thickness for interior or exterior as needed. For shipping limits, compute total size as length + girth, where girth = 2 × (W + H). Round to the carrier’s rule.

From tape reads to a usable spec

1) Base formulas

— Interior to exterior:

OD_L = ID_L + 2×wall, OD_W = ID_W + 2×wall, OD_H = ID_H + wall (top) + wall (base)

— Exterior to interior:

ID_L = OD_L − 2×wall, and so on

2) Girth and chargeable size

Carriers use “length + girth.” I take the longest side as length. I set girth = 2×(width + height). Total size = length + girth. I round up to the next whole inch or 1 cm, per the lane. I also compute dimensional weight3 if needed: (L×W×H)/dim-divisor. This protects margin quotes.

3) Tolerances and flute choices

Corrugated moves with humidity. I set ±1.5 mm for E-flute displays, ±3 mm for B-flute shippers. I lock the flute at RFQ. I note caliper. I avoid last-minute swaps that shift the interior fit.

Calculation cheat-sheet

| Need | Formula | What to note |

|---|---|---|

| Girth | 2×(W + H) | Use external sizes |

| Total size | L + 2×(W + H) | Take L as the longest side |

| Interior size | OD − walls | Subtract two walls per axis |

| Dimensional weight | L×W×H / divisor | Check carrier divisor |

I once saved a launch by re-packing 5,000 crossbow kits with a shorter height and the same footprint. The girth dropped. The total size passed the carrier cap. The client kept the deadline and stayed on budget.

What comes first, length or width or height?

People argue about this. Some say height first. Others say whatever feels right. I do not do that. I lock one order and put it in every email, CAD name, and label.

Always write dimensions as Length × Width × Height. Length is the longest base side, width is the shorter base side, and height is vertical. Keep this order across drawings, quotes, and emails.

Why order matters in production

1* Cross-team clarity

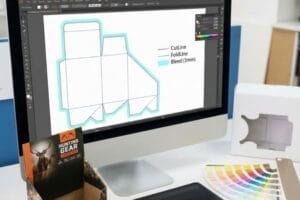

Engineers see L×W×H in CAD. Buyers see it in quotes. Printers see it on dielines. When I keep the same order, no one flips panels or scalpels the wrong crease.

2* Fewer reworks4

A swapped width and height can break pallet plans. A wrong height can fail shelf clearance. I saw a floor display lose a premium end-cap because of an inverted W/H on the drawing. We rebuilt overnight. We never repeat that.

3* Fit with retail rules5

Retailers and 3PLs often list shelves by width and height. If we label our carton as L×W×H, we can map fast. We keep a small table that traces store shelf slots to our L×W×H.

Mapping example

| Context | Definition used | Tip |

|---|---|---|

| My factory specs | L × W × H | Fix this order in templates |

| Pallet layout | L = long face | Align length along pallet depth |

| Shelf planograms | W = facing | Match planogram “facings” to W |

| E-commerce | L = longest side | Carrier math stays consistent |

A simple rule saved me hours. I add it to onboarding for every designer, PM, and sales rep in my team at PopDisplay. The habit scales well when orders grow.

How to measure the total dimension of a box?

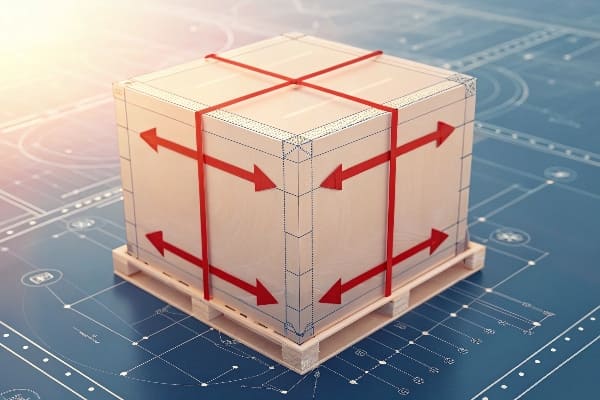

Shipping teams ask for “total dimension.” New staff write the volume. That is wrong. Carriers mean length + girth. I show the steps and a live check you can run with any carton.

Total dimension for shipping equals length + girth. Take the longest side as length. Compute girth as 2 × (width + height). Add them. Compare to the carrier limit for your route. Round up as required.

Field method I use with displays

1* Identify sides

I place the box on its base. I find the longest edge. That is length. The other base edge is width. The standing edge is height. I write them in centimeters and inches. I keep both units on the ticket.

2* Compute and round

I compute girth6 = 2×(W + H). I add length. I round up. If I ship to North America, I also check dimensional weight7. I choose the greater of actual and dimensional weight for cost talks with the client. That avoids surprise invoices.

3* Decide design changes

If total size exceeds a limit, I try three levers. I lower height first. I switch flute to a thinner grade if strength allows. I rotate the pack to change which side is “length.” One small change often moves us under the cap.

Quick audit table

| Step | Action | Why it matters |

|---|---|---|

| 1 | Set L as the longest side | Matches carrier definitions |

| 2 | Compute girth 2×(W+H) | This drives surcharge tiers |

| 3 | Add L + girth | Get total dimension |

| 4 | Round up per carrier | Avoid billing disputes |

| 5 | Check dim weight | Protect margin and quotes |

Personal note: I learned these moves while building Cardboard Displays for hunting products with tight launch windows. My client needed floor units in big-box stores. The first pallet plan failed an oversize rule. I cut height by 8 mm, changed flute, and kept the brand look. The shipment cleared, and the launch date stood.

Conclusion

Measure with one order. Record both OD and ID. Compute shipping size as length plus girth. Write units and tolerances. Check once more before you print or cut.

Exploring external size helps optimize logistics and shelf space, ensuring efficient product placement and transport. ↩

Understanding internal size is crucial for ensuring product fit and avoiding costly errors in packaging. ↩

Understanding dimensional weight is crucial for optimizing shipping costs and ensuring accurate pricing. ↩

Understanding the impact of fewer reworks can enhance efficiency and save costs in production processes. ↩

Exploring this topic can help streamline your product’s compatibility with retail standards, improving sales potential. ↩

Learning how to compute girth can help you optimize shipping costs and ensure compliance with carrier requirements. ↩

Understanding dimensional weight is crucial for accurate shipping costs and avoiding unexpected charges. ↩