Confused by packaging terminology? You aren't alone. But knowing the specific technical difference between these materials is the only way to prevent crushed inventory and "soggy bottom" display failures in retail stores.

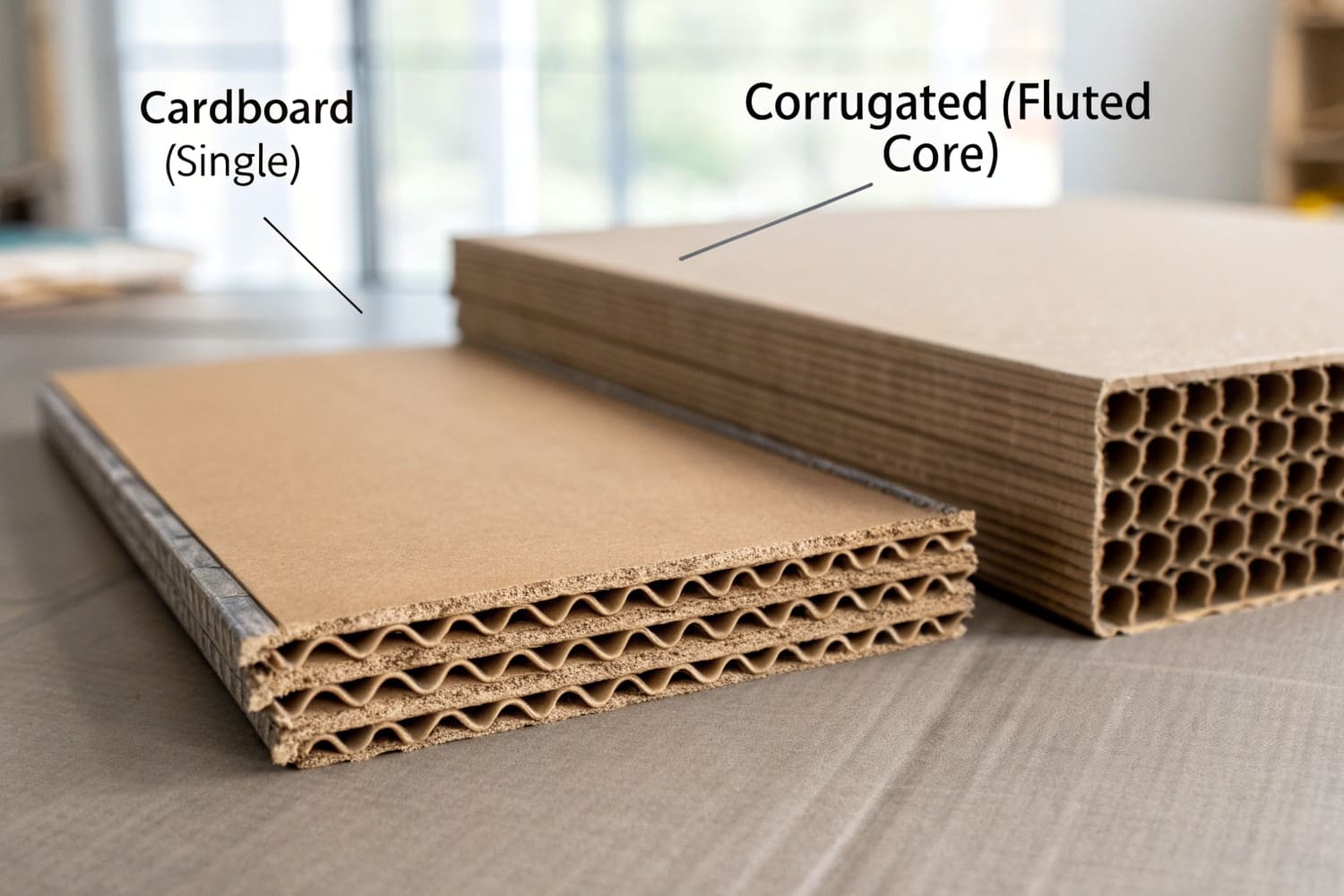

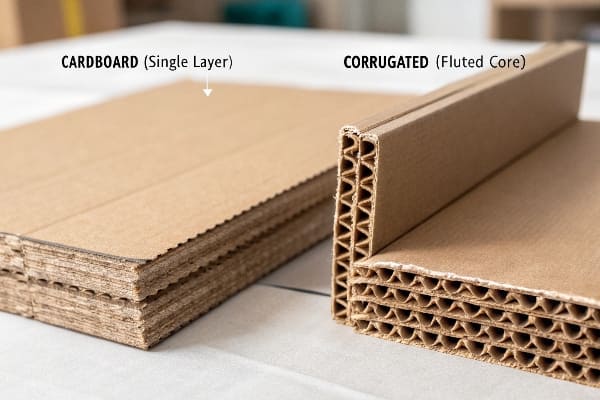

The difference between cardboard and corrugated material lies in their structural makeup. Cardboard refers to heavy-duty paper stock like cereal boxes (folding cartons), whereas corrugated board features a fluted middle layer sandwiched between liners for superior stacking strength (ECT) and impact protection.

Most people use the words interchangeably, but in my factory, knowing the difference saves you thousands in crushed inventory and rejected shipments.

Is corrugated the same as cardboard?

Buying the wrong material ruins your product launch before it starts. Don't let a simple terminology mix-up destroy your marketing budget or your product safety.

No, corrugated is not the same as cardboard. Cardboard is a generic term for single-ply thick paper stock (0.01 inches / 0.25 mm), while corrugated material consists of three distinct layers: an inner liner, an outer liner, and a fluted medium designed for structural integrity.

The Structural Anatomy of Packaging Materials

Here is the messy reality of manufacturing: I once had a client from New York order 5,000 "cardboard displays" for a heavy hunting bow. He meant corrugated, but he asked for cardboard. If I had followed his instruction literally, I would have produced them using Clay Coated News Back (CCNB)1—the stuff cereal boxes are made of. That display would have collapsed the second a 5 lb (2.2 kg) bow was placed on it.

In the industry, "Cardboard" usually refers to Paperboard or Folding Carton stock. It is a single, thick sheet of pulp, usually varying from 10 pt to 36 pt thickness (0.25 mm to 0.9 mm). It is excellent for high-quality printing using a Heidelberg Speedmaster press because the surface is smooth, but it has zero structural spine. It flops over if you try to make it stand up on its own over 12 inches (30 cm) high.

Corrugated Fiberboard2, on the other hand, is an engineering marvel. It uses the physics of arches. It consists of a fluted sheet (the wavy part) glued between two flat linerboards. This creates air columns that provide vertical stacking strength. For a floor display holding 50 lbs (22 kg) of product, we rely on the Grain Direction3 of these flutes. If I orient the grain vertically, that corrugated board can hold a massive amount of weight. If I mistakenly orient it horizontally (which happens if a designer doesn't know the material), the box buckles immediately. It's not just "paper"—it is a structural column disguised as paper. We test this using the BCT (Box Compression Test)4 to ensure it can survive the supply chain.

| Feature | Cardboard (Paperboard/Folding Carton) | Corrugated Fiberboard |

|---|---|---|

| Structure | Single thick ply (Solid) | 3+ Layers (Liner – Flute – Liner) |

| Typical Thickness | 0.010" – 0.030" (0.25 mm – 0.8 mm) | 0.062" – 0.250" (1.6 mm – 6.4 mm) |

| Primary Use | Product packaging (Cereal, Cosmetics) | Shipping boxes, POP (Point of Purchase) Displays |

| Stacking Strength | Low (Relies on product inside) | High (Relies on Flute ECT rating) |

| Print Surface | Smooth (Excellent for photos) | Textured (Risk of washboard effect) |

I often act as a translator between what a client says and what they need. When you say Cardboard Display, I automatically translate that to Corrugated Structure with High-Quality Print. It keeps your product off the floor.

What is the difference between cardboard and corrugated boxes?

A box is just a box until it collapses in a humid truck. The difference lies in the invisible engineering that keeps your goods safe during transit.

The difference between cardboard and corrugated boxes is structural composition. Cardboard boxes use single-ply paperboard suitable for lightweight items, while corrugated boxes utilize a multi-layered fluted structure designed to withstand specific edge crush tests (ECT) and protect heavier goods during transit.

Material Science: Flutes, Liners, and Load Limits

The difference between these boxes usually comes down to the "Soggy Bottom" effect. Cardboard boxes absorb moisture like a sponge. If you ship a cardboard carton in a humid container from Shenzhen to Miami, it arrives soft. It loses its shape.

Corrugated boxes are designed to fight this. We use specific Flute Profiles5 to determine the box's character. For example, B-Flute is roughly 1/8 inch (3 mm) thick and is the workhorse for standard shipping boxes. It offers good puncture resistance and decent stacking strength. However, for retail displays where aesthetics matter, B-Flute can be a nightmare because of the "Washboard Effect." The waves of the flute show through the liner, making your printed logo look rippled and cheap.

To fix this, for high-end boxes (like electronics or cosmetics), we often switch to E-Flute6 or EB-Flute. E-Flute is thinner, about 1/16 inch (1.6 mm), with 90 flutes per foot compared to B-Flute's 47. The tighter waves create a smoother surface for printing but sacrifice some cushioning.

Then there is the liner quality. Cheap corrugated boxes use Recycled Testliner. It's eco-friendly, sure, but the fibers are short. In dry climates like Arizona, recycled liners crack at the fold lines, exposing the brown inside. For premium corrugated boxes, I insist on Virgin Kraft Liner7. The long fibers don't crack, and they resist moisture much better than standard paperboard boxes. It costs about 5% more, but it stops your box from looking like trash after one week.

| Box Type | Material Grade | Max Recommended Load | Durability Risk |

|---|---|---|---|

| Folding Carton | 18pt CCNB | < 2 lbs (0.9 kg) | Tears easily, absorbs water |

| Mailer Box | E-Flute Corrugated | 10-20 lbs (4.5-9 kg) | Good crush resistance, smooth print |

| Shipper Box | 32 ECT B-Flute | 30-50 lbs (13-22 kg) | Washboard effect on print |

| Heavy Duty | 44 ECT BC-Flute | 65-80 lbs (29-36 kg) | Rough surface, strictly industrial |

I use a 50-Touch Rule in my factory. If a box or display can't withstand being handled by 50 customers without looking worn out, the material is wrong. Corrugated passes this test; standard cardboard fails by touch number five.

Is there a difference between cardboard and corrugated cardboard?

Hearing "cardboard" makes structural engineers nervous. Precision in language equals precision in pricing, performance, and preventing supply chain disasters.

Yes, there is a difference between cardboard and corrugated cardboard, primarily in the manufacturing process. Cardboard is a solid pulp sheet produced on a paper machine, while corrugated cardboard is manufactured on a corrugator that bonds fluted medium to linerboards using starch-based adhesives.

Engineering the Layers: Single Wall8 vs. Double Wall9

This is where the "Over-Engineering" trap happens. Clients often think "thicker is better," but that's not always true. Standard "Corrugated Cardboard" (technically Corrugated Fiberboard) comes in Single Wall (3 layers: Liner-Flute-Liner) and Double Wall (5 layers: Liner-Flute-Liner-Flute-Liner).

For a standard floor display in a grocery store, Single Wall (B-Flute) is usually sufficient if we engineer the grain direction correctly. However, if you are selling into Costco or Sam's Club10, the game changes completely. They have a "Club Store Hardline" on packaging. They don't care about your pretty graphics; they care about the 2,500 lb (1,134 kg) dynamic load requirement on their pallets.

If I used standard heavy cardboard (paperboard) or even a weak 32 ECT Single Wall corrugated for a Costco pallet, the bottom layer would be crushed instantly by the forklift. For these scenarios, we must use Double Wall (EB-Flute). This combines the fine printing surface of E-Flute with the structural muscle of B-Flute.

Another critical difference is the adhesive. In corrugated manufacturing, we use starch-based glue. I learned this the hard way: if the glue mix isn't heat-resistant, containers sitting in a 130°F (54°C) truck crossing Texas will delaminate. The liners peel right off the flutes. Solid cardboard doesn't have this risk because it's a solid sheet, but it also lacks the "Safety Factor" capabilities. We engineer corrugated displays with a Safety Factor of 3.511—meaning if it holds 100 lbs (45 kg), we build it to break at 350 lbs (158 kg) to account for humidity fatigue.

| Spec | Single Wall (3-Ply) | Double Wall (5-Ply) | Solid Cardboard (1-Ply) |

|---|---|---|---|

| Composition | 2 Liners, 1 Medium | 3 Liners, 2 Mediums | Compressed Pulp |

| Common Flutes | B, C, E | BC, EB | N/A |

| ECT Rating | 32 – 44 ECT | 48 – 71 ECT | N/A (Measured in Caliper) |

| Best For | Standard Retail Displays | Costco Pallets / Heavy Industrial | Shelf Packaging Only |

If your display collapses, nobody blames the humidity; they blame the brand. I advise spending the extra cents on the correct corrugated grade to ensure your brand stands tall, literally.

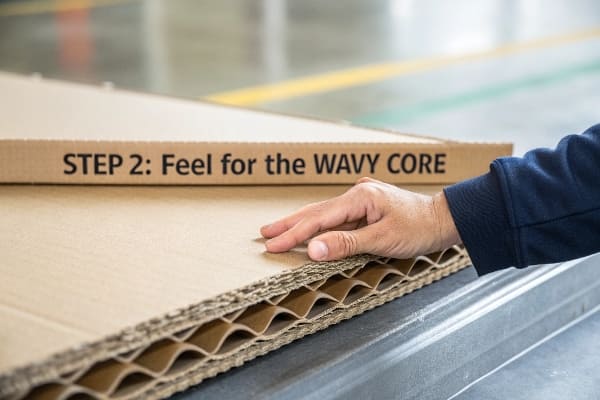

How to know if cardboard is corrugated?

Not sure what you are looking at? A simple visual and tactile check prevents you from ordering the wrong package type and facing rejection at the warehouse.

To know if cardboard is corrugated, check the cut edge for a wavy, fluted layer of paper sandwiched between two flat liner sheets, which creates a distinct "arch" structure that provides thickness and rigidity.

Visual Forensics: Identifying Quality and Structure

Sometimes it is tricky. High-end packaging often uses a technique called Litho-Lamination12. This is where we print on a thin sheet of high-quality "Cardboard" (CCNB) and then glue it onto a "Corrugated" backing. From the outside, it looks like smooth, premium cardboard. But if you look at the raw cut edge, you will see the flutes hiding underneath.

This is actually the "Gold Standard" for retail displays. You get the print quality of cardboard with the strength of corrugated. However, you also need to identify quality corrugated. Here is a factory trick: Look at the color of the inner liner (the inside of the box).

- Dark/Grayish Brown: This is Recycled Testliner13. It's cheaper and weaker. It absorbs water easily.

- Golden/Pine Wood Brown: This is Virgin Kraft14. It is strong, snaps when folded (good tension), and resists moisture.

Also, try the "Thumb Test." Press your thumb hard into the flat surface. If you can easily crush the flutes underneath and leave a permanent dent, it's likely a low-grade recycled medium. If it resists your thumb and springs back, it's high-performance fiber. I often have to show clients that the "Cardboard" they bought from a budget supplier is actually low-grade recycled corrugated that won't survive the trip from the distribution center to the store shelf.

We also check the "Memory" of the material. If you fold a piece of solid cardboard, it creates a sharp, permanent crease instantly. If you fold corrugated, it fights back slightly due to the air volume in the flutes. This resistance is what we call "Bend stiffness15," and it's vital for displays that need to stay square and upright for months in a store like Target or Walmart.

| Inspection Method | Result: Cardboard (Paperboard) | Result: Corrugated |

|---|---|---|

| Edge Check | Solid, consistent density | Visible air gaps and waves (arches) |

| Bend Test | Bends easily in any direction | Resists bending across the grain |

| Thickness | Thin, flexible (Credit card thickness) | Thick, rigid (Structure thickness) |

| Surface | Always smooth | Can be smooth or show "washboard" lines |

Don't guess on material quality. If you are unsure what you are currently using, send a sample to my lab. I will run a fiber analysis and tell you exactly why your current displays are failing or succeeding.

Conclusion

The battle between cardboard and corrugated comes down to one trade-off: Printability vs. Strength. Cardboard (Paperboard) makes your images pop, but Corrugated ensures your product arrives intact. The secret to a winning display is often combining them—laminating a cardboard print sheet onto a corrugated structural skeleton.

Would you like to see how this combination works for your specific product weight? I can create a Free Structural 3D Rendering or send you a Physical White Sample so you can test the strength yourself before you commit to a full order.

Explore this link to understand the applications and limitations of CCNB in packaging materials. ↩

Discover the benefits of Corrugated Fiberboard, a key material in packaging that offers strength and versatility. ↩

Learn how Grain Direction impacts the structural integrity of corrugated materials, crucial for effective packaging design. ↩

Find out why the BCT is essential for ensuring packaging durability and performance in the supply chain. ↩

Understanding Flute Profiles is essential for selecting the right box for your shipping needs. ↩

Explore the benefits of E-Flute for high-end packaging and its impact on print quality. ↩

Learn why Virgin Kraft Liner is preferred for premium boxes and its moisture resistance. ↩

Explore the benefits of Single Wall corrugated cardboard for cost-effective packaging solutions. ↩

Learn why Double Wall corrugated cardboard is essential for durability in heavy load applications. ↩

Discover the specific packaging standards required by major retailers like Costco and Sam's Club. ↩

Understand the importance of a Safety Factor in ensuring the reliability of packaging under stress. ↩

Explore this link to understand how Litho-Lamination enhances packaging quality and durability. ↩

Learn about Recycled Testliner to make informed choices about packaging materials and their environmental impact. ↩

Discover the advantages of Virgin Kraft for strong and moisture-resistant packaging solutions. ↩

Understanding bend stiffness can help you choose the right materials for long-lasting displays. ↩