Popdisplay is a trusted manufacturer and supplier of high-quality cardboard displays in China, with over a decade of experience in the industry. We offer customized sizes, shapes, and designs to perfectly fit your project needs. Our comprehensive one-stop service ensures that every detail is taken care of. Request a quote today and get fast, competitive pricing for your next display project!

Your Trusted Manufacturer of Cardboard displays

Cardboard displays are known for their excellent versatility, strength, and eco-friendly properties. Lightweight yet durable, they are perfect for showcasing products in retail environments. At Popdisplay, we specialize in designing and manufacturing custom cardboard displays tailored to your exact needs. With over a decade of experience, we provide solutions in various sizes, shapes, and designs, all customizable to fit your branding and display requirements. Whether you need a unique design or a specific structure, we have the perfect solution for your project. Contact us today for a personalized quote!

POP UP Cardboard Displays

Built for versatility, our cardboard displays combine lightweight strength with creative potential. Resistant to wear and tear, these displays offer a durable, eco-friendly solution for showcasing your products in retail and trade show settings. With customizable designs, sizes, and branding options, we bring your vision to life while ensuring a lasting impression.

Pallet Cardboard Displays

Popdisplay offers a full range of customizable cardboard displays, designed to meet your brand's needs. Whether you're looking for unique designs, structural adjustments, or specific dimensions, our team is ready to create the perfect display solution for your business. We provide prototypes, free modifications, and high-quality production to ensure satisfaction every time.

Retail Cardboard Displays Shelf

Engineered for reliability, our cardboard displays stands offer exceptional strength while maintaining a lightweight profile. Perfect for both heavy-duty and lighter products, these stands are designed to enhance the visibility of your merchandise. Customizable for all retail environments, they ensure your products are presented with both stability and style.

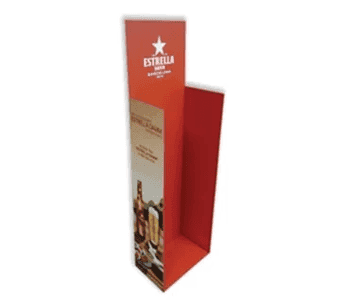

Beer Drink Case Stacker Displays

Point of Purchase displays are designed to capture customer attention right at the moment of purchase. Made from durable cardboard, these displays can be fully personalized to feature your product, brand logo, and promotional messages. Our custom POP displays are an ideal way to drive sales and boost brand awareness.

4 Shelves Floor Display Stand

Eco-Friendly Cardboard Displays

Crafted from sustainable materials, our cardboard displays offer a responsible yet high-performance solution. Designed to be strong and durable, these displays are perfect for businesses that prioritize environmental impact without sacrificing style. Fully customizable, they let your products shine while supporting your brand's green initiatives.

Divider Pocket/Cell Floor Displays

Floor stand cardboard displays are a highly effective way to showcase your products in retail environments. These displays offer a great balance of stability and visibility, making them perfect for point-of-sale areas. Crafted with care, they can be fully customized to match your branding and product needs.

Tray Corrugated Displays Stand

Branded Cardboard Displays

Exude professionalism and creativity with our custom-branded cardboard displays. Designed to align with your brand identity, these displays help highlight your products in the best possible way. With vibrant print options and sturdy structures, these displays not only enhance your product's visibility but also elevate your brand's presence in any retail or trade environment.

4 Side Hang Pegable/Hooks Displays

When durability and easy setup are essential, cardboard floor display stands are the perfect solution. Whether you're showcasing individual products or a series of items, these stands are designed to offer a high-quality presentation that enhances customer engagement and visibility.

Counter Displays

Compact and stylish, Pop-Up Counter Displays bring products right to the customer’s eye level. Great for checkout counters and tabletops, they help drive last-minute purchases. Fully customizable in shape and graphics, these displays showcase small products like accessories, cosmetics, or gadgets while keeping the focus on your brand.

Tailor-Made Cardboard Displays for Your Unique Needs

At Popdisplay, we understand that every project is unique, and we are committed to delivering cardboard displays that perfectly match your requirements. With years of experience in the industry, we've built a reputation for providing high-quality, custom solutions that not only meet but exceed expectations. From custom sizes and shapes to unique branding and design features, we specialize in creating displays that truly reflect your brand and products. Trust us to bring your vision to life with precision and care.

Trust Popdisplay for displays that reflect your brand's image and drive sales in your stores.

Our Tailored Service List:

- Custom Sizes: Whether small countertop displays or large floor stands, we design displays to your exact dimensions.

- Unique Designs: From sleek modern to bold promotional styles, our creative team ensures your display stands out.

- High-Quality Printing: Crisp, vibrant graphics that match your brand's identity perfectly.

- Strong & Durable Materials: We use premium cardboard to ensure your displays can hold the weight of your products.

- Full Customization: Choose from various shapes, sizes, finishes, and features to suit your marketing needs.

More Than Your Cardboard Displays Supplier

With years of experience in creating custom cardboard displays, Popdisplay offers a comprehensive range of solutions to meet the unique needs of every business. We focus on providing high-quality, eye-catching designs with fast delivery and competitive pricing, making us a trusted partner for businesses worldwide.

Cardboard Displays Design Recommendations

Unsure about the best display style for your products? Let our experts guide you in selecting the perfect design that highlights your brand while ensuring functionality and durability.

Customer Support

Need help with your display order? Our team is here to assist. Whether it's design advice, project insights, or assistance with logistics, we offer full support throughout your process.

Extensive Range of Displays

Popdisplay offers a wide variety of cardboard displays options, from point-of-purchase stands to floor displays, all tailored to different product types and retail environments.

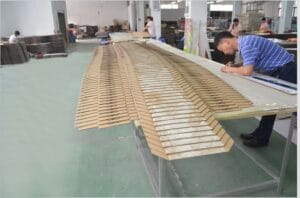

High-Quality Production

With our experienced production team, we ensure that every cardboard displays is crafted with precision and quality, matching your exact specifications for both design and strength.

Why Choose Cardboard Displays from PopDisplay?

At Popdisplay, we are committed to providing outstanding custom cardboard displays solutions. Since our inception, we have specialized in delivering high-quality, eye-catching displays tailored to the unique needs of retail businesses. With our dedicated team and cutting-edge production processes, we ensure that every display is built to maximize your brand's impact.

- 12+Years of Expertise: With extensive experience in the cardboard displays industry, Popdisplay combines a team of skilled designers and engineers with advanced production capabilities to deliver high-quality displays with precision and reliability.

- Competitive Pricing: We provide cost-effective solutions without sacrificing quality. Our efficient manufacturing processes allow us to offer excellent value while ensuring that your displays meet the highest standards.

- One-Stop Solution: Popdisplay offers a full-service solution—from initial design to fast production and delivery. We make it easy for our clients to receive custom displays tailored to their specifications, all with minimal hassle.

Choose Popdisplay, and enjoy the benefits of our expertise, affordable pricing, and comprehensive service that elevates your brand in every retail space.

The Ultimate Guide to Procuring Custom Cardboard Displays

Cardboard displays are essential marketing tools used across various industries, from retail and consumer goods to trade shows and promotional events.

Whether you're a retailer, event organizer, or distributor – this guide reveals industry secrets most suppliers won't tell you. From cost-effective sourcing to maximizing display lifespan – Your step-by-step playbook for dominating promotions with cardboard displays.

Still unsure where to start? 90% of buyers begin with the [New Buyer Playbook] – Your shortcut to avoiding costly mistakes.

Your Journey: [New Buyer Playbook] → [Vetted Supplier Network] → [Total Cost Calculator] → [Engineering Lab] → [Asset Guardian]

Your Complete Procurement Journey

Select the module that best fits your current needs and experience level

New Buyer Playbook

Master the fundamentals and avoid costly rookie mistakes. Learn display types, sourcing strategies, and customization benefits from industry experts.

-

What is a Cardboard Displays?→

-

Applications of Cardboard Displays→

-

Different Types of Cardboard Displays→

-

The Evolution of Cardboard Displays: A Historical Timeline→

-

Characteristics of Cardboard Displays→

-

Understanding Cardboard Displays Products→

-

How Do Cardboard Displays Enhance Product Promotion?→

-

Comparing Cardboard Displays vs. Traditional Display Methods→

-

Cardboard Displays Classifications→

-

How Does a Cardboard Displays Work?→

Vetted Supplier Network

Connect with pre-screened manufacturers and discover quality control secrets. Learn factory specifications and why 200+ brands trust our supply chain.

- 8 Deadly Sins of Sourcing Cardboard Displays from China (And How Top 5% Buyers Avoid Them)

- Overview of Our Cardboard Displays Production Capabilities

- How to Choose a Reliable Cardboard Displays Supplier?

- Our Supply Capacity of Cardboard Displays

- Cardboard Displays Quality Standards

- Our Cardboard Displays Specifications

- Grades of Cardboard Displays

- Quality Assurance for Custom Cardboard Displays

- Key Considerations for Choosing a Cardboard Displays

- Cardboard Displays Solutions: Custom, Durable, and Eco-Friendly

- Key Factors Influencing the Cardboard Displays Manufacturing Process

- Cardboard Displays, Tray, and Shelf Comparison

- Benefits of Using Custom Cardboard Displays

- Considerations When Purchasing Cardboard Displays

Total Cost Calculator

Discover why "cheap" displays cost more long-term. Compare materials, avoid hidden fees, and calculate real ROI with our smart pricing guide.

- Cardboard Displays vs. Other Materials: A Simple Comparison

- Understanding Cardboard Displays Pricing

- 5 Mistakes That Destroy Your Cardboard Displays (And How to Avoid Them)

- Comparison: Cardboard Displays vs. Acrylic Displays

- Comparison: Cardboard Displays vs. Plastic Displays

- Comparison: Cardboard Displays vs. Metal Displays

- Comparison: Cardboard Displays vs. Wood Displays

- Comparison: Cardboard Displays vs. Steel Displays

Engineering Lab

Deep-dive into material science, structural design, and eco-innovations. Perfect for engineers and designers building high-performance displays.

- Cardboard Displays Manufacturing Process

- Physical Properties of Cardboard Displays Compared to Other Materials

- The Production of Cardboard Displays: A Step-by-Step Guide

- Cardboard Displays: Standard vs. Custom Designs

- Cardboard Displays Geometry Design Guide

- Customizable Surface Finishing Options for Cardboard Displays

- Composition of Custom Cardboard Displays

- Key Factors Influencing the Effectiveness of Cardboard Displays Designs

- Cardboard Displays: Components and Construction

- The Role of Protective Coatings: A Superior Solution for Cardboard Displays Durability

- Guidelines for Maximizing the Performance of Your Cardboard Displays

- How to Optimize Your Custom Cardboard Displays Selection?

- How to Choose the Right Custom Cardboard Displays for Retail Promotions?

- Cardboard Displays vs. Other Display Solutions: Key Differences

- Understanding Corrosion and Its Impact on Cardboard Displays Durability

- How Does a Cardboard Displays Maintain Stability?

- Understanding the Impact of Improper Grounding on Cardboard Displays

Asset Guardian

Maximize your investment with expert installation, maintenance, and lifespan extension strategies. Protect your displays from setup to retirement.

- 1Side Effects of Cardboard Displays Usage

- 2Lifespan of Cardboard Displays

- 3Cardboard Displays Use Precautions

- 4Installation and Maintenance of Cardboard Displays

- 5How to Install Custom Cardboard Displays

- 6How We Ensure the Quality of Our Custom Cardboard Displays

- 7Advantages of Custom Cardboard Displays

- 8Choosing the Best Custom Cardboard Displays for Your Business

- 9How to Customize Your Cardboard Displays?

Chapter 1

What is a Cardboard Displays?

A Cardboard Displays is a lightweight, eco-friendly marketing tool designed to showcase products in a visually appealing way. Made from durable, high-quality cardboard, these displays are widely used in retail environments to promote products, enhance brand visibility, and drive sales. The customizable nature of cardboard displays makes them perfect for a variety of industries, from food and beverage to electronics and cosmetics.

Cardboard displays are commonly used in stores, trade shows, exhibitions, and other promotional settings. They can be designed in various shapes, sizes, and configurations, such as countertop displays, floor stands, or pallet displays, depending on the product and placement requirements.

What makes them particularly attractive is their customizability. You can add your branding elements, such as logos, colors, and messaging, to ensure your product stands out. With a combination of affordability, effectiveness, and versatility, cardboard displays are a great way to highlight products while remaining environmentally conscious.

In summary, a cardboard displays is a powerful marketing tool, tailored to suit your specific needs, ideal for improving product presentation and boosting brand awareness in any retail or promotional setting.

Chapter 2

Applications of Cardboard Displays

Custom cardboard displays are an incredibly versatile marketing tool used across various industries to promote products in retail and public spaces. Their unique ability to combine eye-catching designs with practicality makes them essential in areas like retail marketing, trade shows, product launches, and in-store promotions. Let’s explore how custom cardboard displays serve different industries and applications, highlighting their impact on visibility, customer engagement, and sales growth.

Retail Promotions: Used extensively in stores to showcase products such as cosmetics, electronics, toys, and more. These displays help grab customer attention and drive sales by presenting products in an attractive and organized manner.

Point-of-Purchase (POP) Displays: Ideal for placing near checkout counters or high-traffic areas, POP displays encourage impulse purchases by highlighting special offers or new arrivals.

Trade Shows and Exhibitions: At trade shows, competition for attention is fierce. Custom cardboard displays are a perfect solution for standing out in crowded exhibition halls. Their vibrant designs and customizable features allow you to create a memorable booth that attracts visitors and facilitates product interaction.

Promotional Displays: Perfect for marketing campaigns, cardboard displays can be used for product launches, special offers, or seasonal promotions, helping businesses stand out in competitive retail environments.

Event Displays: Whether for corporate events, conferences, or product demonstrations, custom cardboard displays provide a cost-effective and impactful way to present information or products to attendees.

Eco-Friendly Solutions: As sustainable materials, cardboard displays are increasingly used by businesses looking to reduce their environmental footprint while maintaining high-quality marketing materials.

Product Launches: When launching a new product, creating excitement and awareness is crucial. Custom cardboard displays are ideal for this purpose, as they can be tailored to highlight key product features and create an engaging presentation. These displays not only help to catch the attention of potential customers but also guide them toward making a purchase decision.

Point-of-Sale Displays: Custom point-of-sale (POS) displays are designed to capture customer attention right at the checkout counter. These displays are strategically placed to promote impulse buys and reinforce your brand message. Whether it’s a countertop display for a small accessory or a larger floor-standing unit for a more substantial product, these displays make the most of limited space.

Seasonal and Holiday Campaigns: Custom cardboard displays are ideal for seasonal campaigns, especially around holidays and special events. These displays can be tailored to fit seasonal themes, such as Christmas, Halloween, or summer promotions, providing the flexibility to adjust designs quickly and effectively for each campaign.

In-Store Branding: With a variety of design options, these displays can be integrated seamlessly into any store environment, whether you need standalone units or shelf displays. By combining functionality with creativity, custom displays help you create a cohesive and engaging shopping experience that resonates with customers and encourages repeat visits.

In conclusion, custom cardboard displays are a powerful tool for enhancing product visibility, driving customer engagement, and increasing sales. Tailored to fit your business needs, these displays offer a cost-effective, eco-friendly, and highly customizable way to showcase your products across multiple retail environments. Whether for a product launch, seasonal campaign, or in-store promotion, cardboard displays are the perfect solution for elevating your brand’s presence.

Chapter 3

Different Types of Cardboard Displays

Custom cardboard displays come in various shapes and designs to meet specific retail or promotional needs. Here’s a breakdown of the most common types:

Floor Displays: These are freestanding displays designed to be placed on the floor. They are often used for larger products or in high-traffic areas where they can attract attention from a distance.

Countertop Displays: Smaller, compact displays designed to sit on counters or tables. Ideal for showcasing smaller items like cosmetics, gadgets, or impulse-buy products.

Dump Bins: These displays are open containers often used to hold products like snacks, toys, or promotional items. They are designed for bulk products and are great for high-volume sales.

Shelf Displays: Designed to fit within shelving units, these displays help organize products and maximize shelf space while drawing attention to specific items.

Hanging Displays: Suspended from ceilings or walls, these displays are ideal for showcasing lightweight products or marketing materials, giving your display a unique angle.

Endcap Displays: Positioned at the ends of aisles, endcap displays are strategically placed to capture customer attention as they walk by, often featuring special offers or new products.

Each display type is designed to enhance product presentation and improve customer engagement, allowing businesses to choose the right format based on the space and purpose of the display.

Floor Displays

Countertop Displays

Dump Bins

Shelf Displays

Hanging Displays

Endcap Displays

Chapter 4

The Evolution of Cardboard Displays: A Historical Timeline

- Early 1900s – The first cardboard displays are introduced, originally used for simple retail advertising.

- 1930s – Cardboard displays become more common in stores, with brands seeking better ways to showcase products in eye-catching ways.

- 1950s – Cardboard displays structures evolve, with more durable, lightweight designs for better product presentation.

- 1960s – Printed cardboard displays begin to feature more vibrant designs, with brands increasingly using them for point-of-sale promotions.

- 1980s – The use of cardboard displays expands worldwide, with custom designs tailored to specific product types and target audiences.

- 1990s – Digital printing technology emerges, allowing for high-quality graphics and more intricate designs on cardboard displays.

- 2000s – The rise of e-commerce and online shopping further fuels demand for innovative, portable, and eco-friendly cardboard displays for retail and exhibitions.

- 2010s – Sustainable and eco-conscious materials become a key focus in cardboard displays production, meeting modern demands for green marketing solutions.

- 2020s – Advancements in 3D design and prototyping lead to highly customizable and structurally sound cardboard displays, with increasing use in global retail chains and exhibitions.

- Today – Cardboard displays remain a staple in retail environments, offering cost-effective, customizable, and sustainable merchandising solutions.

Chapter 5

Characteristics of Cardboard Displays

- Cost-Effective Solution: Cardboard displays offer an affordable way to showcase your products without compromising on visibility or impact, making them perfect for businesses looking to enhance their branding on a budget.

- Customizable Designs: Tailor every detail of your display, from dimensions to graphics, ensuring your brand message is presented exactly how you envision it. Perfect for creating a unique in-store experience.

- Eco-Friendly Material: Made from sustainable materials, cardboard displays are a green choice for businesses aiming to reduce their environmental footprint without sacrificing quality.

- Lightweight and Portable: Easy to transport and set up, cardboard displays are an ideal choice for events, pop-up stores, and trade shows, offering flexibility for on-the-go promotional needs.

- Sturdy and Reliable: Despite being lightweight, cardboard displays are engineered to be durable and hold up under various conditions, providing a reliable solution for your display needs.

- Versatile for Various Industries: Whether you’re in retail, exhibitions, or even promotional events, cardboard displays can be adapted for various product types, offering a creative solution to showcase anything from cosmetics to electronics.

- Simple Assembly: No need for complex tools or labor—cardboard displays can be assembled quickly and easily, saving you time and effort.

- Eye-Catching and Attention-Grabbing: With vibrant printing capabilities, your cardboard displays can feature bold graphics that catch customers’ eyes, ensuring your products stand out in a crowded market.

- Space-Saving: Cardboard displays can be easily broken down and stored, making them an efficient option for businesses that require flexible storage solutions without taking up too much space.

- Cost-Effective Shipping: The lightweight nature of cardboard reduces shipping costs, making these displays a practical choice for businesses aiming to optimize logistics and lower overall expenses.

- High-Quality Printing: Supports vibrant, high-resolution printing to attract customer attention and enhance brand recognition.

Chapter 6

Understanding Cardboard Displays Products

Cardboard displays products are versatile, eco-friendly promotional tools made from high-quality, sturdy cardboard. Due to their lightweight, customizable nature, and durability, they are widely used for product showcasing in various industries. Some common forms of cardboard displays include:

- Counter Displays: Perfect for retail spaces, showcasing small products at checkout areas.

- Floor Displays: Tall and eye-catching, ideal for showcasing products in high-traffic areas of stores.

- Endcap Displays: Positioned at the end of aisles to attract customers' attention and drive sales.

- Custom Displays: Tailored to fit specific branding needs and product types, ensuring a unique look.

Multiple industries benefit from using cardboard displays:

- Retail: Retailers use cardboard displays to enhance in-store product visibility and drive customer purchases.

- Marketing & Promotions: Brands leverage customized displays for limited-time offers, special events, and new product launches.

- Trade Shows: Easy to transport and assemble, perfect for creating impactful presentations at trade shows and exhibitions.

- Consumer Goods: Manufacturers of packaged goods use cardboard displays to enhance product appeal and streamline retail presentations.

In essence, the adaptability, cost-effectiveness, and environmental friendliness of cardboard displays make them an invaluable tool for enhancing brand visibility and promoting products across various sectors. Whether it's a one-time campaign or an ongoing retail setup, these displays offer a balance of aesthetics, functionality, and sustainability.

Chapter 7

How Do Cardboard Displays Enhance Product Promotion?

Custom cardboard displays work by strategically positioning products in high-visibility areas, drawing customer attention, and boosting engagement. These displays serve as marketing tools that not only showcase products but also communicate your brand’s identity and values in an impactful way.

When placed in retail environments or at trade shows, the displays act as interactive touchpoints that encourage product interaction and increase consumer interest. The creative and functional design of each display ensures that your products stand out, leading to higher foot traffic and potential sales.

By providing an organized and visually appealing way to showcase your offerings, custom cardboard displays effectively enhance brand visibility, reduce clutter, and encourage more consumer interaction, making them a key component in any successful product promotion strategy.

Chapter 8

Comparing Cardboard Displays vs. Traditional Display Methods

When choosing between custom cardboard displays and traditional display methods like permanent fixtures or large-scale metal displays, it's crucial to consider the unique needs of your business, budget, and promotional objectives. Each type of display offers its own set of benefits and drawbacks depending on factors like the size of your campaign, design complexity, and long-term usage.

In general, custom cardboard displays are ideal for short-term, high-impact promotions, especially in retail or event environments where flexibility and ease of use are key. Traditional displays, such as permanent metal or wooden structures, are better suited for long-term installations but often come at a higher cost and can be less adaptable.

The table below provides a detailed comparison between custom cardboard displays and traditional display methods:

| Type | Advantages | Disadvantages |

|---|---|---|

| Cardboard Displays | 1. Highly customizable – Tailor-made with branding, colors, and unique designs. | 1. Limited durability – Best for short-term or seasonal promotions. |

| 2. Lightweight & easy to transport – Saves on shipping costs and allows for quick assembly. | 2. Not ideal for heavy products – May not support excessive weight without reinforcements. | |

| 3. Eco-friendly – Made from recyclable materials, supporting sustainability efforts. | 3. Shorter lifespan – Designed for temporary displays rather than long-term use. | |

| 4. Cost-effective – Lower production costs compared to traditional materials. | ||

| 5. Easy setup & disposal – Can be quickly installed and recycled after use. | ||

| Traditional Displays | 1. Greater durability – Metal, wood, or plastic fixtures last for years. | 1. Higher costs – More expensive to manufacture and transport. |

| 2. Stronger weight capacity – Can hold heavier products without structural concerns. | 2. Limited design flexibility – Harder to customize compared to cardboard displays. | |

| 3. Long-term investment – Suitable for permanent retail fixtures. | 3. More complex setup – Requires professional installation in many cases. | |

| 4. Professional look – Provides a premium appearance for high-end retail environments. | 4. Not eco-friendly – Often made from non-recyclable materials, leading to waste. |

Key Considerations for Choosing the Right Display Type

For seasonal promotions, product launches, or short-term retail campaigns, custom cardboard displays offer a cost-effective, eye-catching, and eco-friendly solution. They allow for maximum brand visibility while keeping production and shipping costs low.

However, for long-term retail fixtures that require high durability and weight capacity, traditional displays may be a better investment, despite their higher cost and lower design flexibility.

Ultimately, the best choice depends on your budget, product type, marketing strategy, and sustainability goals.

→ Back to Table of Contents

Chapter 9

Cardboard Displays Classifications

Cardboard displays are popular in retail marketing due to their versatility, eco-friendliness, and cost-effectiveness. Available in various forms based on design, size, and application, each type of cardboard displays is tailored to meet specific retail and promotional needs. Below is a breakdown of the most common classifications:

| Display Type | Description | Applications |

|---|---|---|

| Countertop Displays | Small, compact displays designed to sit on retail counters. Typically lightweight and easy to assemble. Can be printed with high-quality graphics. | Ideal for impulse purchases, small products, or promotional items placed near checkout counters in stores. |

| Floor Displays | Larger displays designed to stand on the retail floor. Can hold a variety of products, from small items to larger boxes. Often freestanding with sturdy bases. | Perfect for showcasing a wide range of products in aisles, retail floor spaces, or as part of a special promotional campaign. |

| Pallet Displays | Large-scale displays that use pallets as their base. Often used for bulkier or more extensive product displays. Customizable for high-traffic areas. | Commonly used for bulk products, seasonal promotions, or special offers in larger retail spaces and supermarkets. |

| Hanging Displays | Lightweight cardboard displays designed to hang from ceilings or fixtures. Often used for high-visibility promotional purposes. | Ideal for attention-grabbing displays, such as seasonal promotions, or for creating vertical product presentations in stores. |

As a trusted supplier of custom cardboard displays, Popdisplay offers a full range of display solutions tailored to your specific marketing needs. Whether you need countertop, floor, pallet, or hanging displays, we ensure that each product is designed to deliver the maximum impact and durability for your promotional campaigns.

Chapter 10

How Does a Cardboard Displays Work?

A cardboard displays works as a highly effective retail marketing tool designed to attract customer attention, increase product visibility, and boost sales. These displays are strategically placed in retail stores, supermarkets, and promotional areas to highlight specific products or brands.

1. Attracting Customer Attention

Cardboard displays use vibrant colors, custom graphics, and strategic placement to catch the eye of shoppers. With high-quality printing and unique shapes, they differentiate products from standard shelf items, increasing impulse purchases.

2. Providing a Functional Display Space

A well-designed display holds and organizes products efficiently, ensuring easy access for customers. It consists of:

- Shelves or Trays – Securely hold products, preventing movement or damage.

- Side Panels & Backboards – Provide structural support and branding space.

- Header Boards – Feature promotional messages to enhance product appeal.

3. Ensuring Easy Assembly & Placement

Most cardboard displays are designed for quick, tool-free assembly, making them convenient for retailers.

- Flat-pack shipping reduces logistics costs.

- Pre-folded creases & locking tabs allow easy setup.

- Lightweight design enables repositioning in high-traffic areas.

4. Enhancing Brand Marketing

Custom branding elements like logos, slogans, and product details reinforce brand identity. Retailers and brands use displays for:

- New product launches

- Seasonal promotions

- Limited-time discounts

5. Supporting Sustainability & Cost Efficiency

Unlike plastic or metal fixtures, cardboard displays are eco-friendly and cost-effective:

- Made from recyclable materials to support sustainability.

- Lightweight & disposable for easy post-campaign removal.

- Affordable production costs compared to permanent store fixtures.

Conclusion

By combining visual appeal, functionality, and easy assembly, cardboard displays help brands maximize retail exposure and increase sales. Their versatility makes them a preferred choice for point-of-purchase marketing, ensuring a high-impact in-store presence.

At Popdisplay, we specialize in custom cardboard displays designed for maximum visibility, durability, and sustainability. Whether for floor displays, pallet displays, or countertop units, our solutions ensure effective product presentation in any retail setting.

Part 1

8 Deadly Sins of Sourcing Cardboard Displays from China (And How Top 5% Buyers Avoid Them)

Free download

Free download

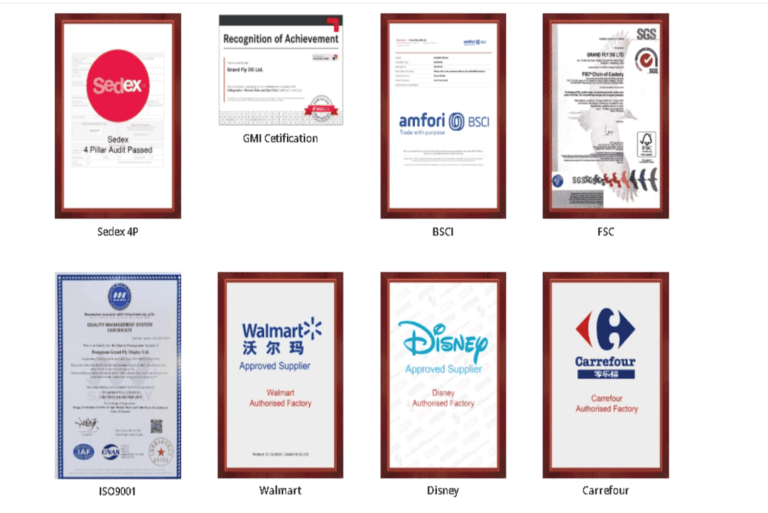

1. Production Quality Control

Ensuring the quality of your cardboard displays is critical. Choose suppliers with international certifications (e.g., ISO, BSCI) and request samples for testing before committing to large orders. Quality control processes before purchasing can help avoid issues like rework or customer complaints due to subpar products.

2. Supplier Selection

When selecting suppliers, focus on their reputation and experience. Platforms like Alibaba and Made-in-China allow you to review supplier histories and customer feedback. Compare multiple vendors to avoid working with unfamiliar or unreliable manufacturers.

3. Price Negotiation

The price of cardboard displays depends on factors such as design, material, and manufacturing process. Clearly communicate your requirements and negotiate prices based on volume or long-term partnerships. Be aware of market pricing to avoid hidden costs from unusually low quotes.

4. Minimum Order Quantity (MOQ)

MOQs vary between suppliers, with customized products typically requiring higher minimums. If your order volume is small, consider negotiating with suppliers to lower the MOQ or explore group purchasing options with other buyers to meet MOQ thresholds.

5. Lead Time and Shipping

Know the supplier's production and delivery lead times to avoid project delays. Ensure your shipping method aligns with both budget and timing needs. Opt for cost-effective shipping options (sea or air freight) to control expenses while meeting deadlines.

6. Custom Design and Production

Suppliers often provide design assistance for custom cardboard displays. Share a detailed design plan and confirm with the supplier before production to prevent any errors. Choose materials that offer both durability and reusability for longer-lasting displays.

7. Tariffs and Import Process

Familiarize yourself with the tariff policies and import procedures when sourcing from China to avoid unexpected costs or delays. Work with a logistics partner to ensure smooth customs clearance and have the necessary documentation ready.

8. Eco-friendly Materials and Sustainability

Sustainability is increasingly important in product sourcing. Choose materials with eco-certifications (e.g., FSC) to reduce environmental impact and improve your brand image. Eco-friendly displays also meet the growing consumer demand for green products.

Part 2

Overview of Our Cardboard Displays Production Capabilities

This table provides a concise and organized view of our Cardboard Displays production specifications.

| Feature | Specification |

|---|---|

| Standard | Custom designs tailored to client needs, high-quality cardboard, eco-friendly materials |

| Grade | Premium, Heavy-duty, Eco-friendly, Luxury, Water-resistant, Custom |

| Display Type | Counter displays, Floor displays, Endcap displays, Shelf displays, Custom displays |

| Size Options | Customizable dimensions: Width: 100mm to 3000mm, Height: 100mm to 2500mm, Depth: 50mm to 1500mm |

| Design Flexibility | Fully customizable graphics, branding, and dimensions to suit product type and marketing strategy |

| Production Method | Die-cutting, Folding, Gluing, Printing (Offset, Digital, or Screen) |

| Finish Options | Matte, Glossy, UV coating, Lamination, Embossing, Spot varnishing |

| Load Capacity | Light-duty to heavy-duty options based on material strength and display requirements |

| Customization | Fully customizable designs with options for print artwork, structural design, and brand colors |

| Delivery Time | Fast turnaround for standard designs, up to 30 days for custom displays (depending on complexity) |

| Surface Finish | Smooth, textured, laminated, or custom finishes for an upscale look |

| Applications | Retail, Trade shows, Point of sale, Marketing promotions, Product launches, Event displays, Brand campaigns |

This guide provides an overview of our Cardboard Displays production capabilities, highlighting the wide range of design, size, and customization options available for businesses in various sectors. Whether you’re looking for a simple countertop display or a large, high-impact floor display, we offer a solution tailored to your needs.

Part 3

How to Choose a Reliable Cardboard Displays Supplier?

When selecting a supplier for your cardboard displays, there are several essential factors to consider to ensure a smooth and successful partnership:

- Industry Expertise: Look for suppliers with a proven history and extensive experience in producing high-quality cardboard displays. A well-established supplier is likely to offer more innovative designs and better product durability.

- Certifications and Standards: Ensure that the supplier follows industry standards and quality certifications. This could include environmental certifications (e.g., FSC for sustainability) and product quality assurances to guarantee reliable and safe products for your retail space.

- Customer Reviews and Testimonials: Read past customer reviews and testimonials to get a sense of the supplier's reliability, the quality of their displays, and their customer service level. Positive feedback from other businesses can give you confidence in their ability to deliver quality products.

- Product Variety: A supplier with a broad range of display designs, sizes, and materials demonstrates their ability to meet diverse business needs. It also gives you flexibility to choose the best option for your product promotion.

- Clear Pricing: A trustworthy supplier should offer clear and transparent pricing, with no hidden charges or unexpected costs. Transparent pricing ensures you get the best value for your investment while helping you stay within budget.

- Design and Customization Support: A top-tier supplier will offer customization options, from design adjustments to branding opportunities, ensuring that the display aligns perfectly with your brand’s image.

- Delivery and Shipping: Consider the supplier’s ability to meet delivery deadlines and manage logistics efficiently. Timely delivery is crucial for your marketing campaigns, so make sure they can meet your schedules.

- Communication: Good communication is key to a successful partnership. Choose a supplier who is responsive and proactive in addressing your questions, concerns, and project-specific needs.

By keeping these factors in mind and conducting thorough research, you’ll be able to find a reliable cardboard displays supplier that can meet your business requirements and support your marketing efforts.

Part 4

Our Supply Capacity of Cardboard Displays

| Specification | Details |

|---|---|

| Customization | Fully tailored size, structure, and branding to match product and retail requirements. |

| Manufacturing Standard | Custom design specifications tailored to retail, promotional, and exhibition display standards. |

| Material Options | ▲ Corrugated cardboard (E-flute, B-flute, C-flute, etc.) ▲ Eco-friendly recyclable materials ▲ Premium Recycled Paperboard ▲ High-Durability Paper with Custom Finishing Options |

| Display Size | Custom sizes, ranging from small countertop displays (as small as 6″) to large floor-standing units (up to 72″) |

| Printing Methods | ▲ CMYK Offset Printing ▲ Flexographic Printing ▲ UV Printing ▲ Spot Colors & Gloss/Matt Lamination |

| Structure Types | Floor Displays, Counter Displays, Pallet Displays, Dump Bins, Hook Displays, Tiered Shelves |

| Load Capacity | Lightweight (≤5kg) / Medium (5-15kg) / Heavy-duty (15kg+) |

| Technical | Precision die-cutting, high-quality printing, CNC machining for complex shapes and sizes |

| Condition | Flat-packed, easy-to-assemble displays, ready-to-use for events or retail environments |

| Surface Finishing | Glossy/Matt Lamination, Spot UV, Embossing, Hot Stamping, Varnishing |

| Surface Treatment | Matte, glossy, or laminated finishes for enhanced durability, visual appeal, and protection against wear and tear |

| Assembly | Pre-assembled or flat-packed with easy setup design |

| Shape | Custom shapes including free-standing, countertop, shelf, hanging displays, and tray displays for specific needs |

| Usage Scenarios | Supermarkets, Retail Stores, Trade Shows, Pharmacies, Electronics Shops, Shopping Malls |

| Application | Retail marketing, point-of-sale displays, trade shows, brand promotions, product exhibitions, and product showcases |

→ Back to Table of Contents

Part 5

Cardboard Displays Quality Standards

At Popdisplay, we follow rigorous quality standards to ensure that each cardboard displays meets your needs for durability, visual appeal, and functionality. Different regions have their own established standards, with the USA and Europe being key contributors. Our production processes are aligned with global best practices, ensuring that every display not only meets your expectations but exceeds them.

Our quality standards are guided by:

- ISO 9001:2015 – Quality management systems to ensure consistent quality in all our processes.

- FSC Certification – Ensuring sustainable sourcing of the materials used in our cardboard displays.

- SGS Testing – To ensure that the displays meet environmental and material safety standards.

- ASTM D1974

China’s quality standards include:

- GB/T 4857.4-2002

- GB/T 4894-2002

Industry Standards for Cardboard Displays

Common international quality benchmarks include:

- ISO 9001: Quality management system ensuring consistent product quality.

- ISO 14001: Environmental standards for sustainable material sourcing.

- FSC Certification: Ensures the cardboard is sourced from responsibly managed forests.

- ASTM D1974

Key Material and Strength Standards:

- ECT (Edge Crush Test): Measures the stacking strength of corrugated cardboard.

- Bursting Strength Test: Ensures resistance to punctures and pressure.

- Printing Quality Standards: Guarantees high-resolution graphics and color accuracy.

Standard Material Specifications Based on Thickness and Strength

| Thickness (mm) | Material Type | Recommended Use |

|---|---|---|

| 1.5 – 3.0 | Single-Wall Corrugated | Lightweight displays for indoor promotions |

| 3.5 – 5.0 | Double-Wall Corrugated | Medium-duty retail product displays |

| 6.0+ | Triple-Wall Corrugated | Heavy-duty displays for bulkier products |

To give you a better understanding, let’s break down these standards according to display size, material grade, and the corresponding standard references:

| Display Size (mm) | Material Grade | Standard References |

|---|---|---|

| 500 x 300 to 1500 x 1000 | Premium Corrugated Cardboard | ISO 9001, FSC, ASTM D1974 |

| – | Heavy-Duty Double Wall | GB/T 4857.4-2002, ISO 9001 |

| – | Recycled Paper Grade | GB/T 4894-2002, ASTM D1974, FSC Certification |

| – | Single Wall Corrugated | ISO 9001, ASTM D1974, FSC |

| – | High-Strength Cartonboard | ISO 9001, ASTM D1974, FSC |

These standards ensure that our cardboard displays not only maintain their structural integrity under varying conditions but also showcase your products with high-quality print finishes, whether for retail, trade shows, or promotional events. With the right materials and processes in place, your display will perform consistently and make a lasting impression on your audience.

Part 6

Our Cardboard Displays Specifications

Custom cardboard displays are crafted with precision to meet the specific needs of each retail environment. The materials, design, and structural elements are selected to ensure durability, functionality, and visual appeal. Below is a table outlining the key specifications for custom cardboard displays:

| Category | Details |

|---|---|

| Standard | Custom-designed to meet retail, supermarket, and promotional display requirements. |

| Material Options | – Corrugated Cardboard (E-flute, B-flute, C-flute) – Double-Wall & Triple-Wall Cardboard – Eco-Friendly, Recyclable Materials |

| Display Size | Custom sizes available, ranging from small countertop units to large floor-standing displays. |

| Weight Capacity | – Light Duty: Up to 5kg per shelf – Medium Duty: 5-15kg per shelf – Heavy Duty: 15-30kg per shelf |

| Technical Process | Die-cutting, Laminating, Printing (Offset, Flexo, Digital), Gluing, UV Coating, Embossing. |

| Surface Treatment | – Glossy or Matte Lamination – Spot UV – Hot Stamping – Embossing – Water-based Coating |

| Main Display Types | – Floor Displays – Countertop Displays – Pallet Displays – Dump Bins – Hanging Displays |

| Display Styles | – Free-standing Displays – Shelved Displays – Hooked Displays – Foldable & Easy-Assembly Designs |

| Printing | Full-color, high-resolution printing options available |

| Customization Options | Custom shapes, logos, graphics, and branding elements |

| Design Features | Sturdy structure, easy assembly, and lightweight design |

| Assembly | Easy setup with no tools required; simple interlocking design |

| Packaging | Flat-packed or pre-assembled for efficient shipping and storage |

| Design Life | Durable for short-term to long-term use, typically 1-3 years for seasonal or promotional use |

| Key Features | – Custom Branding & Full-Color Printing – Sturdy & Lightweight Structure – Space-Saving & Cost-Effective – 100% Recyclable & Sustainable Materials |

| Application | Ideal for use in retail stores, supermarkets, trade shows, convenience stores, and promotional campaigns to enhance product visibility and sales. |

At Popdisplay, we specialize in custom cardboard displays solutions that are durable, visually striking, and easy to assemble. Whether you need countertop, floor-standing, or pallet displays, we ensure high-quality displays tailored to your brand and marketing goals.

Part 7

Grades of Cardboard Displays

Cardboard displays vary in material strength, durability, and intended applications. Choosing the right grade ensures optimal product support, longevity, and branding impact. Below is a detailed breakdown of the most common cardboard displays grades:

| Grade | Description | Key Features | Durability | Primary Uses | Strengths | Applications |

|---|---|---|---|---|---|---|

| Single-Wall (E-Flute, B-Flute, C-Flute) | Lightweight and cost-effective, suitable for short-term use. | Thin profile, smooth surface, easy to print on. | Low | Temporary promotions, light products | Cost-effective, easy to assemble, great for branding. | Countertop displays, small product promotions. |

| Double-Wall (BC-Flute, EB-Flute) | Increased durability with better load-bearing capacity. | Stronger structure, better shock absorption. | Medium | Mid-weight retail products, extended promotions | Enhanced strength, more stable than single-wall. | Floor-standing displays, medium-weight products. |

| Triple-Wall (AAA-Flute, BAA-Flute) | Heavy-duty, offering maximum strength and stability. | Maximum durability, high weight resistance. | High | Heavy-duty retail, warehouse displays, bulk sales | Superior load-bearing, long-lasting support. | Pallet displays, bulk promotions, and high-weight products. |

This table helps you identify the best cardboard displays grade based on your product type, retail setting, and durability needs. At Popdisplay, we offer custom, high-quality cardboard displays solutions designed for maximum impact, strength, and product visibility.

Part 8

Quality Assurance for Custom Cardboard Displays

At Popdisplay, we are committed to delivering high-quality custom cardboard displays that meet and exceed your expectations. To ensure top-notch performance and durability, each display goes through a stringent quality control process. Our Quality Assurance Team conducts a series of tests to assess the integrity, design accuracy, and material durability of every display before it reaches you. Only after passing these rigorous checks are the displays approved for shipment. This thorough process reflects our dedication to providing reliable and superior products that align with your retail and promotional needs.

Our quality assurance process includes the following key testing parameters:

| Test Items | Test Conditions | Qualification |

|---|---|---|

| Material Strength | Compression and load test | No deformation or bending |

| Print Quality | Visual inspection and color consistency check | No color inconsistencies |

| Structural Integrity | Weight test and load-bearing test | No collapsing or warping |

| Coating & Design Accuracy | 3D rendering comparison with final product | 100% design accuracy |

| Surface Finish | Gloss/matte lamination durability test | No peeling or bubbling |

| Durability Under Stress | Exposure to humidity and temperature variations | No warping or fading |

| Moisture Resistance | 48-hour humidity exposure test | No warping or weakening |

| Eco-Friendliness | Recyclability test | Meets eco-friendly standards |

| Customization Precision | Test assembly and disassembly process | Quick and easy setup |

| Durability for Long-Term Use | Stability test under extended display conditions | Minimum 6 months of use without damage |

| Transport Durability | Vibration and impact test in simulated transit | No major damage upon delivery |

Through these stringent tests, we ensure that our custom cardboard displays are durable, functional, and aesthetically pleasing. Each display is designed to effectively showcase your products and enhance your brand’s presence while maintaining its integrity in diverse retail environments.

→ Back to Table of Contents

Part 9

Key Considerations for Choosing a Cardboard Displays

When selecting a cardboard displays for your retail or promotional needs, it's essential to evaluate several factors to ensure you choose a solution that best meets your goals:

- Display Requirements: Begin by defining your display needs, including size, weight capacity, and the specific products you want to showcase. This will help you choose the most appropriate cardboard displays that highlights your products effectively and suits your space.

- Customization Options: Consider how much customization you require, from the display's structure and dimensions to the design and branding. A well-customized display can reinforce your brand's identity and make your products stand out.

- Design and Durability: Evaluate the quality of the display's design and materials. Ensure that the cardboard is strong enough to handle the weight of your products and withstand handling in various retail environments. A well-designed display will also be eye-catching and draw customers' attention.

- Manufacturer Reputation: Partner with a reliable supplier known for high-quality, durable displays. A trustworthy manufacturer should offer strong customer service, timely deliveries, and support throughout the entire process from design to production.

- Cost-effectiveness: Consider your budget and whether the manufacturer offers competitive pricing without compromising quality. Look for flexible options that allow for cost savings, especially if you plan on ordering in bulk or need multiple designs for different products.

Ease of Assembly & Transport: Consider flat-pack designs for cost-effective shipping and easy setup. Tool-free assembly with pre-folded lines and interlocking tabs can save time and reduce labor costs for retailers.

Eco-Friendliness & Sustainability: Opt for 100% recyclable and biodegradable materials to meet sustainability goals. Displays made from FSC-certified cardboard are preferred by eco-conscious brands and retailers.

By carefully considering these factors, you can ensure that the cardboard displays you choose will effectively showcase your products, elevate your brand, and provide long-lasting results in your retail or promotional setting.

Popdisplay specializes in high-quality, customizable cardboard displays that cater to your specific promotional and retail needs. Whether you need simple tabletop displays or large-scale floor stands, we offer tailored solutions to ensure your products get the attention they deserve.

Part 10

Cardboard Displays Solutions: Custom, Durable, and Eco-Friendly

Cardboard displays are an essential marketing tool for promoting products effectively while ensuring sustainability. Here’s a simplified breakdown of the different types of cardboard displays we offer, highlighting their features and applications.

| Category | Definition | Key Features | Examples/Methods |

|---|---|---|---|

| Cardboard Displays | The broadest category encompassing any display solution made from cardboard used to showcase and promote products in retail environments. | Includes a variety of designs, shapes, and sizes to fit different products and marketing needs. | Custom countertop displays, floor-standing units, pallet displays, and promotional stands. |

| Custom Displays | A type of cardboard displays specifically tailored to fit the exact branding and size requirements of the product being showcased. | Fully customizable design, color printing, and dimensions to match your product and brand image. | Personalized product stands, shelf displays, and promotional units designed for specific products. |

| Eco-Friendly Displays | A category of cardboard displays made from recycled or sustainable materials to meet the growing demand for environmentally conscious solutions. | Made from recyclable or biodegradable materials that minimize environmental impact. | Recycled cardboard displays for eco-conscious brands, biodegradable packaging stands, and sustainable shelf displays. |

| Modular Displays | Displays designed with interchangeable parts that can be adapted for different product sizes and layouts. | Flexible components allow easy adjustments, perfect for seasonal or product line changes. | Modular racks and adjustable floor-standing units for multi-product displays. |

In summary, Cardboard Displays encompass a wide range of solutions, from Custom Displays to Eco-Friendly Displays, offering flexibility and sustainability. Whether you need a tailored display to match your product's size and branding or a more modular, eco-conscious solution, our cardboard displays provide an effective and cost-efficient way to attract customers and enhance product visibility.

Part 11

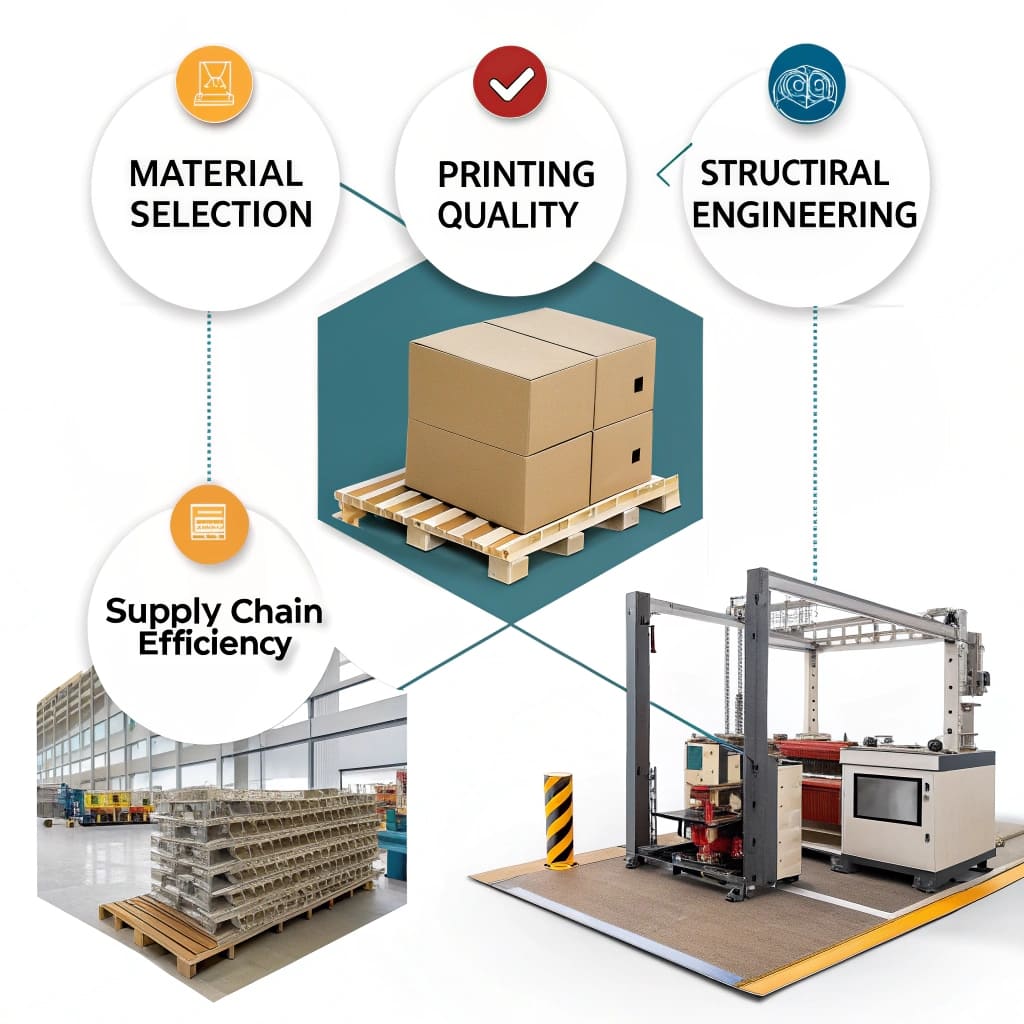

Key Factors Influencing the Cardboard Displays Manufacturing Process

Creating high-quality cardboard displays that stand out requires careful attention to several crucial factors. Here are the top influences that shape the cardboard displays production process:

- Design and Customization: Tailoring the display's design to your specific brand and product is essential. Custom shapes, sizes, and colors are key to creating a unique and eye-catching display.

- Material Quality: The strength and durability of the cardboard used are vital. High-quality materials ensure the display can hold products securely and withstand transport without damage.

- Printing Quality: Clear, vibrant prints are crucial for attracting attention. Ensuring high-quality printing methods avoids issues like color discrepancies and ensures your branding is well-represented.

- Structural Integrity: The design must account for the weight of the products it will display. Proper structural design and reinforcements prevent the display from collapsing or becoming unstable.

- Production Process: Efficient production methods, including precise cutting, folding, and assembly, play a significant role in achieving consistent quality across batches.

- Environmental Factors: Sustainable and eco-friendly materials are becoming increasingly important. Ensuring the display is made from recyclable or biodegradable materials appeals to environmentally conscious consumers.

- Transportation and Packaging: Proper packaging is essential to prevent damage during shipping. Well-protected displays arrive in perfect condition, ready for use.

- Lead Time and Delivery: Meeting tight deadlines is crucial. Timely delivery of displays ensures they are available for product launches and marketing campaigns without delays.

By effectively managing these factors, manufacturers can produce high-quality, durable, and visually appealing cardboard displays. These key considerations help ensure that your displays are not only functional but also a powerful tool in promoting your products and brand.

Part 12

Cardboard Displays, Tray, and Shelf Comparison

At Popdisplay, we understand that selecting the right cardboard displays solution is key for effectively showcasing your products. Below is a comparison of our cardboard displays, cardboard trays, and cardboard shelves, highlighting their key characteristics and common applications to help you make an informed decision.

| Product | Definition | Production Characteristics | Applications |

|---|---|---|---|

| Cardboard Displays | Custom-designed display units made from high-quality cardboard, designed to attract attention and promote products. | Crafted to meet specific product dimensions and branding needs, using durable materials with high-quality printing finishes. | Used in retail marketing, product promotions, point-of-sale displays, and trade shows. Ideal for eye-catching showcases and product launches. |

| Cardboard Tray | Flat, shallow containers made from corrugated cardboard, typically used for holding multiple items together. | Produced for efficient stacking and easy handling, often with custom shapes and sizes. | Commonly used in supermarkets, retail stores, and warehouse environments for multi-product displays, bulk product storage, and organized displays. |

| Cardboard Shelf | Shelf-style cardboard structures designed to hold products in a tiered or upright format. | Built for easy assembly and reusability, available in various sizes to accommodate a wide range of products. | Used in retail environments, trade shows, and promotional events to display multiple products in an organized and accessible way. |

Part 13

Benefits of Using Custom Cardboard Displays

Custom cardboard displays provide a powerful and cost-effective solution to showcase products and boost brand presence in retail and promotional environments. These displays are designed with the specific needs of businesses in mind, offering a variety of key benefits:

- Increased Product Visibility: Custom cardboard displays are designed to attract attention and highlight key products, ensuring that they stand out in busy retail spaces and at events.

- Enhanced Brand Awareness: With custom graphics and branding, these displays reinforce the brand identity and message, helping to create a lasting impression with customers.

- Cost-Effective Marketing: Compared to other display options, cardboard displays offer a budget-friendly solution for businesses looking to maximize their promotional efforts without a hefty investment.

- Eco-Friendly Solution: Made from recyclable materials, custom cardboard displays provide an environmentally responsible alternative to other promotional displays, contributing to sustainability goals.

- Easy to Assemble and Transport: These displays are lightweight, flat-packed for easy transportation, and quick to assemble, making them an ideal choice for businesses with limited space or resources.

- Flexible Customization: Custom cardboard displays can be tailored to suit a wide range of product types, from small items to larger products, and can be designed in various shapes and sizes to meet specific promotional needs.

- Boosted Impulse Purchases: Positioned strategically in high-traffic areas, these displays can encourage impulse buys by making products more accessible and appealing to customers.

- Durability and Strength: With strong, reinforced cardboard, these displays are designed to hold products securely, ensuring they last throughout the duration of the campaign without compromising on their appearance.

- Professional Appearance: Custom designs ensure that displays maintain a high-quality and professional look, aligning with the brand's image and enhancing the overall shopping experience.

- Versatility: Suitable for various industries, including electronics, cosmetics, food, and beverages, ensuring broad application.

- Space Optimization: Custom-built to fit specific retail spaces, maximizing product display efficiency without taking up unnecessary room.

- Scalability: Whether for seasonal promotions, product launches, or long-term displays, cardboard solutions can be easily adjusted for different campaigns.

In summary, custom cardboard displays offer a versatile, effective, and environmentally friendly solution to elevate product presentation and boost brand visibility while keeping costs low and ensuring ease of use.

Part 14

Considerations When Purchasing Cardboard Displays

When selecting cardboard displays for your retail or marketing needs, it’s important to make an informed decision. To ensure you choose the right display for your specific requirements, here are several key factors to consider:

- Display Type & Size: Depending on your product and promotional goals, select the appropriate display type (e.g., counter, floor, endcap) and size. Ensure the display’s dimensions match the space available and accommodate your products effectively.

- Material Strength: The sturdiness of the cardboard is critical, especially for heavier products. Choose between standard, heavy-duty, or reinforced cardboard based on the weight and size of the items to be displayed.

- Customization: Customization can make your display stand out. Whether you need custom graphics, unique shapes, or brand-specific colors, make sure the display can be tailored to align with your marketing message and aesthetic.

- Surface Finish: The finish of your cardboard displays affects both its durability and visual appeal. Options like glossy, matte, or lamination will influence how well your display looks in-store and how long it lasts under various conditions.

- Production Time & Lead Time: Check the lead time for the production and delivery of your display. A quick turnaround is crucial, especially if you have tight marketing campaigns or product launch timelines.

- Cost vs. Quality: While it’s tempting to choose the least expensive option, it’s important to balance cost with the durability and visual appeal of the display. Investing in a higher-quality display often leads to better long-term results.

- Environmental Impact: If sustainability is important to your brand, consider eco-friendly cardboard displays made from recycled materials or biodegradable options.

- Supplier Reliability: Select a supplier with a strong reputation for delivering quality displays on time. A reliable partner will not only provide excellent products but also offer design advice and ensure your displays meet your marketing needs. Work with trusted manufacturers like Popdisplay who have experience in delivering high-quality, reliable cardboard displays.

- Size & Dimensions: Verify that the display dimensions align with your product size and the available retail space.

- Printing & Graphics Quality: The print quality of your display is crucial. Choose a supplier that offers high-quality graphics to make your products stand out.

- Certifications: Ensure the manufacturer adheres to relevant certifications, such as ISO standards or sustainability certifications, to guarantee product quality and eco-friendliness.

- Display Purpose: Consider where and how the display will be used, whether in-store, trade shows, or promotional events, to select the right materials and design.

- Customer Support: Evaluate the level of customer service offered by the supplier to handle your inquiries and any issues that may arise.

- After-Sales Service: Check if the supplier provides post-purchase support, including assistance with assembly or handling returns.

- Product Reviews: Look for customer testimonials and case studies to gauge the supplier's reliability and product quality.

- Packaging and Transport: Ensure the supplier’s packaging is robust enough to prevent damage during shipping, ensuring your displays arrive in perfect condition.

By considering these factors, you’ll be equipped to choose a cardboard displays that suits your promotional objectives, enhances your branding, and performs effectively in a retail or marketing environment.

Module 1

Cardboard Displays vs. Other Materials: A Simple Comparison

Custom cardboard displays offer unique advantages, but how do they compare to other materials like wood, plastic, and metal? Below is a detailed breakdown to help you choose the right display solution for your business:

| Feature | Cardboard | Wood | Plastic | Metal |

|---|---|---|---|---|

| Cost | Low | Higher due to material and labor | Moderate to high depending on type | High due to material and manufacturing costs |

| Durability | Moderate (can be less durable in wet conditions) | High (long-lasting) | High (resistant to weather) | Very high (can withstand harsh conditions) |

| Weight | Lightweight | Heavy | Varies (can be lightweight or heavy) | Heavy |

| Eco-Friendliness | Highly recyclable and eco-friendly | Not typically recyclable | Depends on type, some plastics are recyclable | Often recyclable, but can be energy-intensive to produce |

| Design Flexibility | Highly customizable (easy to print and shape) | Limited by wood structure, difficult to print on | Easy to mold into different shapes, but harder to print | Limited in terms of customization and printing |

| Strength | Sufficient for most retail applications | Very strong, ideal for heavy products | Varies (can be very strong or fragile) | Extremely strong, ideal for heavy-duty use |

| Customization | Fully customizable with printing and die-cutting | Limited due to rigid material | Can be shaped but harder to print on | Limited, mostly requires engraving or decals |

| Portability | Easy to move due to lightweight material | Heavy and difficult to transport | Varies depending on material thickness | Heavy and not easily portable |

| Setup Time | Quick and tool-free assembly | Requires tools and manual labor | Moderate, may require assembly tools | Time-consuming, often needs screws or welding |

| Storage & Shipping | Flat-packed for cost-efficient shipping | Bulky and expensive to store and transport | Depends on type, some can be stackable | Requires significant space and high shipping costs |

| Production Time | Fast production with quick turnaround | Longer due to cutting, sanding, and finishing | Moderate, requires molding and curing | Long production time due to complex fabrication |

| Temperature Resistance | Low (can warp in high humidity) | High (resistant to temperature changes) | Varies by material (some plastics can handle heat) | Excellent (withstand extreme heat and cold) |

| Applications | Retail, trade shows, promotional use | High-end displays, furniture, long-term installations | Retail, packaging, high-performance displays | Industrial, heavy-duty retail applications |

This comparison helps highlight how cardboard displays are often the best option for businesses seeking a balance of cost, customization, and eco-friendliness, especially when compared to more expensive and heavier materials.

By considering the unique strengths of cardboard displays, you can make an informed choice that fits both your budget and marketing goals.

Module 2

Understanding Cardboard Displays Pricing

When considering cardboard displays pricing, it's important to understand the factors that influence its cost. As a trusted manufacturer of cardboard displays, Popdisplay is committed to explaining each factor that affects the price of your customized display solutions.

- Material Quality: The cost of the cardboard material is one of the most significant factors in pricing. Higher quality materials ensure durability, strength, and a longer lifespan for your display. Prices may vary depending on whether you choose standard or premium cardboard, and as market demand changes, material prices can fluctuate accordingly.

- Custom Design and Printing: The complexity of your design and the printing process will also impact the final price. Displays with intricate designs, multiple colors, or high-quality printing require more time, effort, and advanced equipment. As a manufacturer, Popdisplay provides fully customized design services that can be adapted to your branding needs.

- Production Volume: Larger orders tend to reduce the per-unit cost, as economies of scale kick in. Bulk orders may come with discounts, while smaller orders may come at a higher per-unit cost due to setup and material usage.

- Design Complexity: More complex display designs that require detailed prototyping, special folding techniques, or additional features (e.g., removable sections, integrated lighting) will affect pricing.

- Shipping and Handling: Shipping costs vary depending on the size of the order and delivery location. Packaging and logistics are also factored into the final price to ensure the displays arrive in perfect condition. We offer reliable and efficient shipping options to ensure timely deliveries at competitive rates.

Popdisplay believes in transparent and competitive pricing. Once we understand your specific needs, we will provide a detailed quote tailored to your project requirements. Get in touch with us to find the best cardboard displays solutions at a price that works for you.

Module 3

5 Mistakes That Destroy Your Cardboard Displays (And How to Avoid Them)

Proper maintenance and care of your cardboard displays are crucial to ensure they remain in excellent condition and continue to represent your brand effectively. Here are some key tips to help you maintain the longevity and appearance of your displays:

Regular Cleaning

Clean your cardboard displays regularly to remove dust, dirt, and stains. Use a soft, dry cloth to wipe down the surface. For more stubborn marks, a slightly damp cloth with mild soap can be used—just ensure the display is completely dry afterward. Avoid harsh chemicals or abrasive cleaning tools that could damage the printed graphics.Check for Wear and Tear

Periodically inspect your displays for any signs of damage, such as bent edges, torn corners, or fading prints. If you notice any wear, address it immediately to prevent further deterioration. Small repairs can often be made quickly to keep your display in top condition.Avoid Moisture and Humidity

While cardboard displays are designed to be durable, prolonged exposure to moisture can weaken the material. Keep displays in dry environments, especially in areas with high humidity. If your display is exposed to moisture, ensure it is dried out thoroughly before reusing it.Proper Storage

When not in use, store your cardboard displays in a clean, dry area to prevent them from being exposed to dust, moisture, or extreme temperatures. Storing displays upright and flat helps to preserve their shape and avoid warping.- Avoid Direct Sunlight

While cardboard displays are designed to be durable, prolonged exposure to direct sunlight can cause colors to fade and weaken the material. Position your displays in shaded areas to maintain vibrant colors and ensure the material lasts longer.

By following these simple care and maintenance steps, you can ensure that your cardboard displays stay in great shape, keeping your branding fresh and professional for longer periods, and maintaining their impact in any retail setting.

Module 4

Comparison: Cardboard Displays vs. Acrylic Displays

Cardboard and acrylic displays are both popular choices for retail marketing, each offering unique features suited to different needs. While cardboard displays are known for their flexibility, affordability, and eco-friendliness, acrylic displays are prized for their modern look, durability, and premium feel. Here's a comparison to help you understand the key differences between cardboard displays and acrylic displays:

| Property | Cardboard Displays | Acrylic Displays |

|---|---|---|

| Strength | Strong enough for most promotional purposes, but can be prone to damage from heavy items | Very durable, resistant to impact and breakage |

| Weight | Lightweight, easy to transport and set up | Heavier, may require more effort for transportation |

| Cost | More affordable, budget-friendly option | Generally more expensive due to material and manufacturing |

| Customization | Highly customizable in design, size, and print options | Limited customization in terms of design, but offers high-quality finishes |

| Eco-Friendliness | Eco-friendly, often made from recycled materials, 100% recyclable, sustainable | Non-biodegradable, Less eco-friendly, harder to recycle compared to cardboard |

| Durability | Suitable for short-term or seasonal promotions | Ideal for long-term use with a sleek, professional look |

| Appearance | Can be creatively designed with full-color graphics | Offers a polished, clear, and modern aesthetic |

| Transparency | Opaque or printed designs, not see-through | Transparent, ideal for showcasing products with clear visibility |

| Setup/Assembly | Quick and easy to assemble, requires no tools | Requires tools and more time for setup |

| Transportability | Space-efficient, can be flat-packed for easy storage | Bulkier and requires more storage space |

The choice between cardboard and acrylic displays depends on your display's purpose, budget, and the level of visual impact you want to achieve. Cardboard displays offer a cost-effective and eco-friendly option with high customization, making them perfect for temporary or promotional displays. On the other hand, acrylic displays are ideal for businesses seeking a durable, premium display with a modern look for longer-term use.

→ Back to Table of Contents

Module 5

Comparison: Cardboard Displays vs. Plastic Displays

Cardboard and plastic displays are two widely used options for retail and promotional setups, each bringing different advantages. Cardboard displays are well-known for their cost-effectiveness, flexibility, and sustainability, while plastic displays offer sturdiness, a sleek appearance, and resistance to wear and tear. Here's a detailed comparison of cardboard displays and plastic displays to help you determine which best fits your needs:

| Property | Cardboard Displays | Plastic Displays |

|---|---|---|

| Strength | Strong enough for most retail needs but can be prone to bending or breaking under heavy use | Very durable and resilient, able to withstand long-term use |

| Weight | Lightweight and easy to transport | Heavier than cardboard, may require more effort for setup and transportation |

| Cost | Generally more affordable, a budget-friendly choice | Typically more expensive due to material and manufacturing |

| Customization | Highly customizable in design, size, and printed graphics | Limited customization compared to cardboard, more focused on structure |

| Environmental Impact | Eco-friendly, often made from recycled materials, 100% recyclable, biodegradable | Less eco-friendly, Non-biodegradable, difficult to recycle compared to cardboard |

| Durability | Best suited for short-term or temporary use, can get damaged easily | Built for long-term durability and more resistant to wear and tear |

| Appearance | Can be printed with vibrant, eye-catching designs | Offers a sleek, glossy finish and modern look |

| Transparency | Typically opaque or printed with custom graphics | Can be clear or opaque, allowing better product visibility |