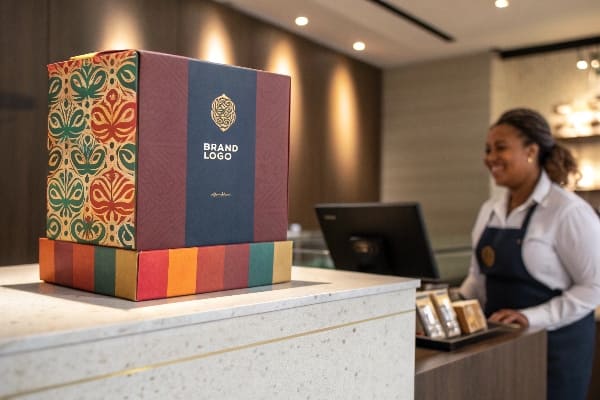

Many buyers fear dull shelves that make products vanish; I faced that worry, too, until custom display boxes pushed my items to the front of shoppers’ minds.

Custom product display boxes are branded packages sized and shaped for a specific item, printed with targeted graphics, and engineered for strength so the product stands out and sells faster.

A plain box hides value, yet a good display reveals worth. Stay with me, and I will break down every part of this topic so you can order the right box the first time.

What are custom display boxes?

My first trade-show booth looked empty, and prospects walked past. That pain made me search for a display that fit only my SKU and screamed my logo.

Custom display boxes are point-of-sale packages built around one product or a small set, printed in brand colors, cut to a unique die-line, and delivered ready to merchandise.

How a display box differs from a shipping carton

Display boxes live on counters, shelves, or pallet heads. They must invite a quick grab, resist touch, and collapse flat after use. In my factory I start with corrugated or SBS board, laser-score folds, add gloss or matte varnish, then apply a crash-lock base so retail staff pop it open in seconds.

| Key Aspect | Display Box1 | Regular Carton2 |

|---|---|---|

| Goal | Sell | Protect |

| Print Coverage | 4-color, high ink | Often one color |

| Structure | Die-cut window, header | Simple rectangle |

| Setup Time | Under 5 s | Not critical |

| Shelf Life | Weeks to months | Until delivery |

Steps I follow for every order

- Design brief. I ask for SKU size, retail channel, and launch date.

- 3-D render. My team sends a PDF and AR model so you can spin it on screen.

- Prototype. We score, cut, glue one unit; you drop in product and push for tweaks.

- Compression test3. I stack 12 layers and monitor deflection; only boxes passing 32 kg stay.

- Mass run. Three lines run 24 h to meet tight launch windows.

With each loop, the box becomes an unpaid salesperson who never sleeps yet keeps margins healthy.

What are custom retail boxes?

When a retail partner asked me for shelf-ready packs that slide straight from pallet to aisle, I saw a gap between distribution crates and flashy displays.

Custom retail boxes are shelf-ready containers that travel through the supply chain closed, then tear open along a perforation to convert instantly into a product tray with branded panels.

Why stores love shelf-ready packs

Retail labor costs rise. A clerk can open fifty shelf-ready packs4 per hour but only twenty loose items. That speed wins placement with chains like Walmart and Tesco.

| Benefit for Store | Result for Brand |

|---|---|

| Faster restock | Guaranteed eye-level slot |

| Less damage | Lower returns |

| Clean visual lines | Higher perceived value |

| Easy facing count | Accurate sell-through data |

Building a retail-ready solution

Simple outer lines. I keep outer dimensions modular—400 × 300 mm footprints lock on Euro pallets.

Easy open tape. A single rip-strip reveals the front flap.

Strong inner cell. Dividers stop crush yet lift out quick.

Graphics that guide. Arrows and color codes show staff which way faces forward.

I learned this after shipping crossbow displays to David from Barnett Outdoors; his team cut hours from planogram resets, and he reordered before hunting season started.

What is a custom box?

Clients sometimes ask for “just a box,” but vague words lead to generic results. My answer focuses on purpose.

A custom box is any packaging unit with dimensions, materials, coatings, and artwork engineered for one brand’s functional and marketing requirements instead of standard catalogue sizes.

Core elements that make a box truly custom

1. Dimension control5

I measure the master product, add assembly tolerance, cushioning, and legal labeling zones. Tight sizing cuts freight cost by up to 15 %.

2. Material selection6

Kraft corrugate suits dry foods; coated duplex suits cosmetics; recycled greyboard wins eco-scores. My lab tests burst, edge crush, and Cobb water uptake.

3. Print and finish

CMYK offset hits fine gradients; flexo matches large runs. I offer spot UV on the logo and soft-touch lamination when a premium feel sells.

4. Special features7

A window invites a try-before-buy; RFID labels help inventory; QR codes link to how-to video.

| Custom Variable | Options | Impact |

|---|---|---|

| Board Grade | E-flute, F-flute, B-flute | Strength vs. weight |

| Coating | Gloss, matte, anti-scratch | Perception |

| Closure | Tuck-top, magnetic, ribbon | Unboxing experience |

| Insert | Foam, pulp, cardboard | Protection, eco image |

I recall shipping a magnetic-closure sample to a luxury tea brand. They loved the snap sound so much they used it in ads.

What are the benefits of custom boxes?

I used off-the-shelf cartons in my early days. Units arrived safe, yet sales grew slow. Custom packages changed that tide.

Custom boxes lift brand recognition, improve protection, reduce logistics costs, support sustainability goals, and create memorable unboxing that spurs word-of-mouth.

Five gains you can bank on

1. Brand power8

A Pantone-matched logo prints once; customers remember it for years. Nielsen reports 64 % of buyers pick a product because package design caught them.

2. Better fit, less waste

A snug interior cuts filler, so you pay for fewer trucks and meet retailer waste targets.

3. Product safety9

Right board grade and inner cushion lower returns. One of my sporting-goods clients saw damage claims drop from 3 % to 0.4 %.

4. Security and compliance

Tamper-evident tape and serialized QR codes fight counterfeits. This is vital for supplements and tech.

5. Customer delight10

Social feeds amplify creative boxes. A well-timed unboxing video can beat paid ads.

| Benefit | Metric to Track | Typical Improvement |

|---|---|---|

| Sell-through | Units per week | +20 % |

| Return rate | % units returned | −60 % |

| Freight cost | $ per unit | −10 % |

| Social mentions | Posts per month | +150 % |

| Repeat orders | Months to reorder | −30 % |

Making benefits real

I walk each buyer through a sample cycle without fees. We tweak graphics until their engineer smiles and the marketer claps. My three CNC sample tables can cut prototypes within 48 h, and DHL gets them worldwide in another three days. That speed matters when a launch date is locked.

Conclusion

Custom product display boxes turn packaging from cost center to silent salesman; choose the right style, and sales speak for themselves.

Explore how display boxes can enhance product visibility and sales in retail environments. ↩

Learn about the essential role regular cartons play in protecting products during shipping and storage. ↩

Discover the importance of compression tests in ensuring packaging durability and product safety during transport. ↩

Explore how shelf-ready packs can streamline operations and enhance product visibility in stores. ↩

Understanding dimension control can help you optimize packaging costs and improve product presentation. ↩

Choosing the right material is crucial for product protection and brand image; explore expert insights on this topic. ↩

Special features can enhance customer experience and product appeal; learn how to leverage them effectively. ↩

Understanding brand power can help you leverage design and recognition to boost sales and customer loyalty. ↩

Exploring product safety can reveal strategies to reduce returns and enhance customer trust in your brand. ↩

Discovering ways to create customer delight can lead to increased engagement and brand loyalty through innovative packaging. ↩