Confused by the many kinds of cardboard boxes? Wrong choices lead to damaged goods and wasted cash. This guide removes the guesswork and shows the safe path to strong, cost-smart packaging.

A cardboard-box guide lists key box styles, strength grades, sizing rules, recycling payouts, and start-up tips, letting shippers, sellers, and recyclers choose, reuse, and profit with clarity.

To get the full picture, stay with me. I move fast, share factory stories, and keep every point practical so you can act today.

What is the difference between RSC and HSC boxes?

Most people stack RSC and HSC cartons on the same pallet, then learn the hard way that they behave differently in transit. Let’s solve that pain before the next shipment breaks.

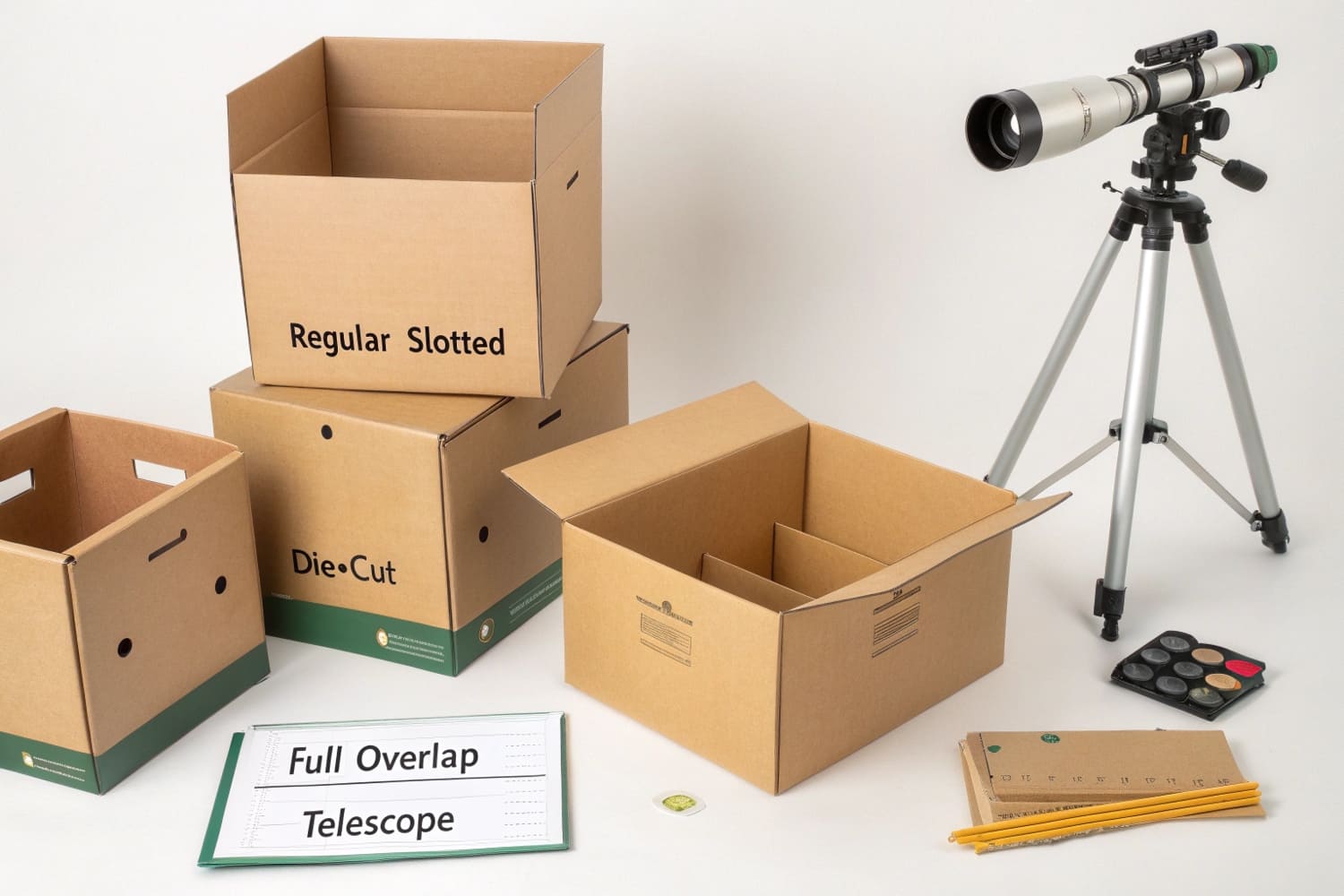

RSC boxes have four full-depth flaps that meet in the center, while HSC boxes have no top flaps and shorter side flaps, making RSC stronger and HSC better for open-top display.

Structure, strength, and spend

When I first exported displays to a big-box retailer, I shipped everything in RSC cartons1. They arrived safe but cost eight percent more in material than the job needed. My next batch used HSC cartons2 with a separate lid. Unit cost dropped, but one pallet collapsed because the lid added no vertical support. The lesson: structure must match load.

| Feature | RSC (Regular Slotted Carton) | HSC (Half Slotted Carton) |

|---|---|---|

| Top flaps | Four full flaps meet | None; lid optional |

| Bottom flaps | Four full flaps meet | Four full flaps meet |

| Vertical stacking strength | High, thanks to full flaps | Moderate, depends on lid |

| Assembly speed | Slow, needs taping top and bottom | Fast, only bottom taped |

| Best use | Shipping heavy or fragile goods | Retail bins, quick loading |

Choosing the right one

- Weight test: If the load is over 20 kg, default to RSC.

- Display goal: If customers need to reach inside, pick HSC but add corner-post reinforcements.

- Labor math: In fast-moving warehouses an HSC saves up to 40 seconds per pack cycle.

- Brand print: HSC lets you print a seamless front face, handy for promotional graphics.

Cost is not the only metric. Use compression-strength data3 and stack-height limits laid out by ASTM D642 or your local standard. A quick lab test costs little and prevents recall nightmares.

What are the three types of boxes?

You see endless box codes online, yet most jobs rely on just three core types. Picking outside this trio usually means over-engineering or paying for a die you never reuse.

The three core box types are corrugated shipping boxes, paperboard folding cartons, and rigid boxes; each serves shipping, retail packaging, and luxury presentation in that order.

Function first, fancy later

My first crossbow display went in a glossy rigid box. It looked premium but doubled freight because rigid board wastes space. A seasoned buyer challenged me to prove the upgrade paid off. Sales lift was tiny. I switched to a corrugated F-flute mailer4 with a paperboard sleeve. Same shelf appeal, half the cost.

| Type | Material | Typical flute/caliper | Primary role | Cost range |

|---|---|---|---|---|

| Corrugated shipping box | Kraft liner + fluted medium | B, C, E, F | Protect goods in transit | Low |

| Paperboard folding carton | SBS or CCNB | 0.3 – 0.6 mm | Retail shelf and inner packs | Medium |

| Rigid box | Greyboard wrapped with printed sheet | 1.2 – 3 mm | Luxury gifts, electronics | High |

Matching product to package

- Drop resistance: Corrugated absorbs shock, so choose it for anything heavier than a coffee mug.

- Shelf exposure: Paperboard folds flat, prints bright, and pops open fast on the line.

- Perceived value: A rigid box signals premium quality but only makes sense when margin justifies it.

Sustainability watch

Rigid boxes are the hardest to recycle because they often include magnets, ribbon, and glue. Folding cartons and corrugated are widely accepted curbside. When a buyer asks for “eco,” show them an unbleached paperboard mock-up first.

How much money do you get for recycling cardboard boxes?

I once filled a 20-foot container with used cartons, dreaming of easy cash. The scrapyard’s number crushed me. Rates swing weekly and differ by region. Let’s pin down what you can really earn.

Recycling facilities in the U.S. pay roughly 1 – 4 ¢ per pound for baled OCC (old corrugated containers), translating to about 20 – 80 USD per ton, depending on market demand.

Market forces in plain words

Cardboard is a commodity named OCC #115. Its spot price moves with global demand for shipping boxes. When e-commerce booms, mills buy more scrap; when warehouses slow, prices dip.

| Region | Recent low (USD/ton) | Recent high (USD/ton) | Current average* |

|---|---|---|---|

| Midwest | 25 | 90 | 60 |

| West Coast | 30 | 100 | 70 |

| Northeast | 20 | 85 | 55 |

*Figures from May 2025 brokers.

Maximizing your payout

- Bale on-site: A tight bale earns 10–15 USD more per ton than loose.

- Keep it clean: Wax-coated, wet, or food-soiled board gets rejected or down-priced.

- Time the sale: Watch PPI Pulp & Paper Week6 or RISI updates; a 10 USD swing per ton is common monthly.

- Leverage volume: Mills offer contract premiums for 40 tons plus7. My factory stacks three production-line offcuts into one bale a day, locking a benchmark rate for the quarter.

Side hustle math

A retail chain store producing 5 tons of OCC monthly might net 300 USD at the current average. After baler lease and labor, profit is slim but still offsets disposal fees. Viewed as an environmental duty and cost saver, not a fortune maker.

How to start a cardboard box business?

Many dream of “printing money” with boxes, yet most fail before the first order ships. I burned through savings on a used slotter-printer before I learned to sell value, not paper.

Start a cardboard box business by validating niche demand, securing reliable sheet supply, leasing essential converting equipment, meeting certification standards, and building repeat B2B accounts before expanding capacity.

From plan to first pallet

I broke the journey into four clear stages. Follow them and you sidestep my costly detours.

| Stage | Key actions | Typical cost (USD) | Common traps |

|---|---|---|---|

| Market proof8 | Interview at least 20 potential buyers; gather sample specs | 0 – 2,000 | Skipping face-to-face talks |

| Supply chain | Contract board sheets, inks, and tooling | 5,000 – 15,000 | Relying on one mill |

| Production setup | Lease/finance flexo printer-slotter, die-cutter, baler | 50,000 – 150,000 | Over-sizing machinery |

| Sales & compliance | Gain ISO or FSC, set MOQ policy, hire account rep | 10,000 – 30,000 | Ignoring repeat order terms |

Practical tips I wish I knew

- Niche trumps mass: I focused on custom point-of-purchase displays. Margins stay high because few plants want short runs with eight-color print.

- Prototype speed9: Own a digital sample table. The ability to ship a sample within 24 hours closes half my deals.

- Certify early10: A simple FSC claim opens doors with U.S. retailers that refuse non-certified packaging. Fees are small compared to lost contracts.

- Cash flow realism: Customers pay 30–60 days after receipt. Line up a working-capital loan or negotiate deposit terms.

- Waste into profit: Trim scraps into filler pads and sell to e-commerce clients. This turns a disposal cost into an add-on product.

Scaling without sinking

Add a second shift before adding a second machine. Train operators through equipment suppliers; skilled labor prevents jams that ruin an entire print run. When orders outgrow capacity, lease extra space near your main plant to avoid forklift traffic jams that slow loading docks.

Conclusion

Boxes look simple, yet the right choice, recycling plan, and business model each hide big profit swings. Use these lessons, test quickly, and let every pallet teach the next one.

Explore the benefits of RSC cartons, including their strength and suitability for heavy or fragile goods, to optimize your shipping strategy. ↩

Learn about HSC cartons and how they can enhance retail displays and save time in packing processes, making them ideal for quick loading. ↩

Understanding compression-strength data is crucial for ensuring product safety during shipping; explore its importance in packaging design. ↩

Explore the advantages of corrugated F-flute mailers, including cost-effectiveness and shelf appeal, to enhance your packaging strategy. ↩

Understanding OCC #11 is crucial for anyone involved in the cardboard market, as it directly impacts pricing and demand. ↩

PPI Pulp & Paper Week provides valuable insights into market trends that can help you make informed selling decisions. ↩

Learning about contract premiums can help you maximize profits when selling cardboard, especially in bulk. ↩

Understanding market proofing can help you validate your product idea and avoid costly mistakes. Explore this resource for insights. ↩

Improving prototype speed can significantly enhance your business efficiency and customer satisfaction. Check out this link for effective strategies. ↩

Early certification can open doors to new markets and clients, making it a crucial step in your business strategy. Learn more about its benefits here. ↩