Customers judge products fast. Weak boxes break, colors fade, shelves look messy, and sales drop. I have watched launch days fail because packages collapsed. I stop that with strong corrugated displays.

Corrugated and plain cardboard give retail packs that are light, tough, flat-shipping, brand-ready, and easy to recycle, so stores cut freight cost and keep shelves neat while goods stay safe.

Smart packaging keeps shoppers looking and keeps buyers ordering. Stay with me and learn the real wins and risks of every board layer I use each day on the factory floor.

Why is corrugated cardboard good for packaging?

Broken products cost more than any box. Many brands still wrap gear in flimsy sleeves, then wonder why refunds rise. I learned this lesson during my first U.S. order ten years ago.

Corrugated cardboard protects by trapping air in rigid flutes, spreads shock, survives stacking, and weighs little, so shipping stays cheap while goods arrive whole and bright.

Strength and Cushion

Air pockets sit between two liner sheets. They act like tiny springs. When a courier drops a box, the flutes bend, not the item.

Cost and Weight

Paper is cheap and light. Shipping rates use weight. Less weight means less cost. That saving goes straight into margin or marketing.

Print and Brand

Smooth outer liners take bright ink. I run six-color presses that match any Pantone code. A bow-hunter graphic looks sharp beside a crossbow sample.

| Feature | Benefit |

|---|---|

| Double-wall flutes | Survive 70 kg crush load |

| Kraft liners1 | Resist moisture on rainy docks |

| Die-cut folds | Set up in 3 seconds on shelf |

| Soy inks | Safe for food and easy on landfills |

My Guangzhou plant tests every design with drop rigs and edge-crush gauges. We fail samples on purpose, then thicken weak spots. That process means David at Barnett Outdoors never sees a dented bow limb in Oregon.

What is a corrugated packaging?

Confusion starts with names. Some buyers mix “corrugated” with “cardboard.” I did that before running my own line. Let me clear it up.

Corrugated packaging is a three-layer paperboard with wavy paper (fluting) glued between flat liners, formed into boxes, trays, or displays for transport and retail use.

Anatomy

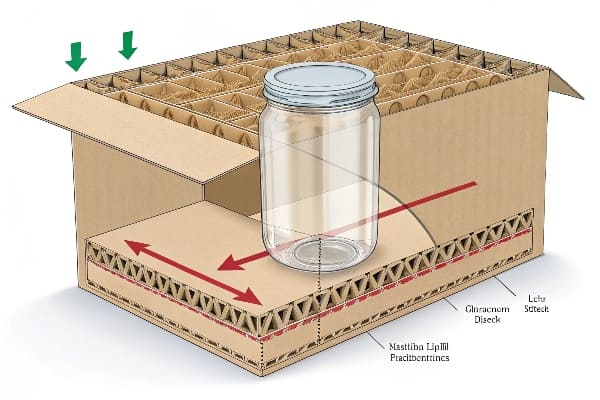

The middle flute height decides strength. A-flute2 is tall, shields fragile glass. B-flute3 is short, prints clean. C-flute4 sits between. When I ship crossbows, I often glue B and C together for mixed loads.

Production

We feed rolls of kraft into a corrugator. Steam softens starch glue. Rollers press waves. Hot plates dry sheets. At 180 m per minute, mistakes cost thousands, so my crew checks glue lines every 30 minutes.

| Component | Job |

|---|---|

| Inner liner | Faces product, needs low dust |

| Flute | Takes vertical force |

| Outer liner | Shows print, meets shopper |

Use Cases

Shippers, shelf-ready packs, dump bins, and pallet skirts all start from the same blank. By swapping flute mix, I meet airline weight limits or warehouse stack limits without new tooling.

What is a disadvantage of corrugated cardboard?

No material is perfect. During my early runs, moisture bowed panels and ruined deadlines. That lesson stays with me.

Corrugated cardboard loses strength when wet, dents under puncture, and needs bulk space, so poor storage or rough metal hooks can still damage goods.

Moisture Risk

High humidity lowers edge crush by up to 40 %.5 I now seal loaded cartons in poly bags when exporting by sea and add desiccant packs.

Space

Flats ship thin, but setup boxes eat room. Retailers with narrow aisles may prefer fold-back displays. I design knock-down units that snap in place with tabs6.

| Issue | Simple Fix |

|---|---|

| Rain during loading | Wax-coated outer liner |

| Piercing from tools | Extra paper ply or corner guards |

| Slow assembly | Pre-glued auto-bottom |

Sustainability Debate

Some argue wax lining hurts recycling. I switch to water-based coatings that pass U.S. fiber mills7. This keeps green-minded buyers happy without risking damp docks.

What are the advantages of cardboard box packaging?

Cardboard looks old-school but keeps winning orders. Two years ago my largest repeat client swapped plastic clamshells for printed boxes and saw returns fall.

Cardboard boxes cost little, fold flat, print vivid graphics, cushion shocks, recycle easily, and accept custom sizes fast, helping brands launch quick while hitting eco goals.

Speed to Market

Digital plotters cut samples in one hour.8 Barnett’s engineer sends CAD. I score, fold, ship overnight. Their trade-show booth shows the real piece, not a render.

Eco Story

Paper boxes boost curbside recycling rates.9 Many chain stores now demand it. Meeting that rule keeps shelf space open.

| Advantage | Why It Matters |

|---|---|

| Low tooling cost | Small runs stay profitable |

| High ink holdout | Brands match colors across SKUs |

| Easy labeling | Stickers adhere better than on PE |

| End-of-life value | Paper mills pay for bale pickup |

Consumer Experience

A neat brown box signals craft and honesty.10 I watch shoppers tap lids, smell paper, then add to cart. Touch still sells.

What is cardboard packaging called?

Names change across regions. Buyers search wrong terms and miss suppliers. I guide them with clear words.

Cardboard packaging is often called paperboard, fiberboard, carton board, or simply carton, depending on thickness and end use.

Paperboard vs Corrugated

Paperboard11 is single-ply, under 1 mm thick. Think cereal boxes. Corrugated is multi-ply with flutes. Mixing terms leads to wrong quotes. I once shipped 5 000 flat cereal sleeves to a client who needed double-wall crates. We fixed fast, but freight hurt.

| Local Term | Common Use |

|---|---|

| Chipboard | Inner shoes supports |

| SBS board | Luxury cosmetic sleeves |

| Kraft carton12 | Eco food packs |

| Triple wall | Export machinery crates |

Speak the Same Language

During quoting I send a small glossary13. This cuts emails by half and saves both sides from late surprises.

Conclusion

Corrugated and plain cardboard, when chosen with clear goals, give strong, light, and green retail packs that guard products and lift brand value while keeping costs in line.

Learn about the moisture-resistant properties of Kraft liners and their importance in shipping. ↩

Explore the unique properties of A-flute and how it protects fragile items during shipping. ↩

Learn about B-flute’s clean printing capabilities and its role in efficient packaging solutions. ↩

Discover the balance C-flute offers and its applications in various shipping scenarios. ↩

Understanding the impact of humidity on edge crush strength can help improve packaging strategies and reduce damage during transport. ↩

Learning about knock-down units can optimize space and efficiency in shipping and retail environments. ↩

Exploring water-based coatings can enhance sustainability in packaging while ensuring compliance with recycling standards. ↩

Explore how digital plotters enhance efficiency and speed in production, crucial for businesses aiming for quick turnaround times. ↩

Learn about the environmental benefits of paper packaging and its impact on recycling, which is increasingly important for consumers and retailers alike. ↩

Discover the psychological effects of packaging on consumer behavior and how it influences purchasing decisions, especially in craft markets. ↩

Understanding the differences can help you choose the right packaging for your products, ensuring quality and cost-effectiveness. ↩

Kraft cartons are eco-friendly and versatile, making them a great choice for sustainable packaging solutions. ↩

A glossary can streamline communication, reduce misunderstandings, and enhance efficiency in business dealings. ↩